Our business

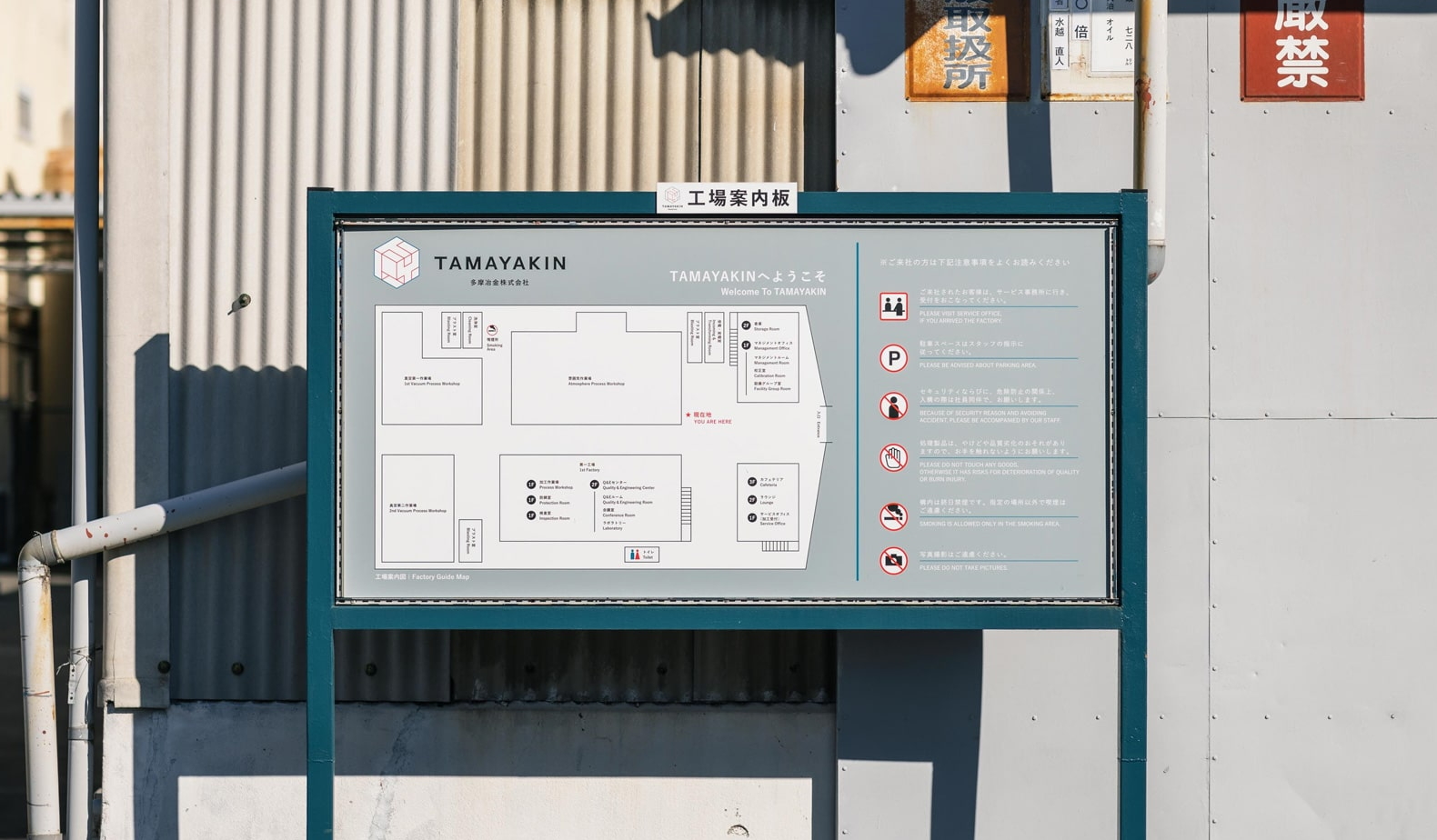

Tamayakin offers heat treatment services on a contract basis at two plant locations; Tokyo (Japan) and Dalian (China).

At both locations, we offer heat treatment for a variety of processes, ranging from general machine parts to aircraft parts, under high-level quality assurance system.

Tamayakin’s plant in Japan deals with a variety of process needs, ranging from small lots and prototype to high-volume production while the plant in China excels at mass production.

Our business

Tamayakin offers heat treatment services on a contract basis at two plant locations; Tokyo (Japan) and Dalian (China).

At both locations, we offer heat treatment for a variety of processes, ranging from general machine parts to aircraft parts, under high-level quality assurance system.

Tamayakin’s plant in Japan deals with a variety of process needs, ranging from small lots and prototype to high-volume production while the plant in China excels at mass production.

Heat treatment services

offered by Tamayakin

There is a large variety of metals around us to play different roles and support our life and society.

In recent years, Tamayakin has focused on heat treatment on aircraft parts, becoming one of the hard-to-find heat treatment plants in the world that has acquired a number of certificates for aircraft parts, including a worldwide certificate, Nadcap.

By virtue of the sizable human resources in the quality assurance system and R&D departments that are almost comparable with the number of plant workers, we enjoy a favorable reputation of the quality of our products, technology, and an ability in new business development.

Heat treatment services offered by Tamayakin

State-of-the-art Distortion Reduction Processing

At TAMAYAKIN, we not only perform ordinary heat treatment, but also distortion reduction treatment using state-of-the-art technology. Distortion reduction technology is essential to the manufacture of high quality parts, as distortion can change the dimensions and shape of a part, adversely affecting its function and performance.

Nickel alloyed with different metals depending on the purpose, such as corrosion resistance, workability, and heat resistance

See more detailCopper alloy facilitating heat transfer, including yellow brass, bronze, and phosphor copper, and those used as anticorrosion material

See more detailAluminum alloy added with different types of element to improve the properties

See more detailTitanium alloy added with different types of element to enhance the merit and improve the demerit of titanium

See more detailTamayakin supports

worldwide machine

industry by providing

heat treatment services

Tamayakin is a heat treatment company independent from any particular corporations or industries. In addition, the company has established “multiproduct small-lot production system” to accommodate flexibly our clients’ various needs. This way, we have expanded the scope of our business activities over the years.

Today, Tamayakin is contributing to the business development of companies in main industries, including aviation, space, and defense, as well as precision machinery, electric components, and racing car accessories manufacturers.

ndustrial sectors Tamayakin has been involved

Reliability of

Tamayakin’s

heat treatment services

Heat treatment is one of the important processes that could adversely affect human life depending on the product quality. Therefore, this process is designated as a “special process” that requires validation of the process. Moreover, acquisition of certificates through process check is demanded in many occasions. Especially in manufacturing of aircraft parts, the certificates are considered as very important part in the evaluation.

Tamayakin has acquired many different certificates that are required in the aircraft industry.

Major certificates acquired from external agencies

Acquired 1999

ISO 9001 quality management system

Obtained in 2009

JIS Q 9100 Quality management system for aerospace

Obtained in 2012

Nadcap International Aerospace Industry Special Process Certification

Obtained in 2016

Heat treatment of Rolls-Royce engine components

Initial acquisition of ISO14001

2015 Environmental management system in 2010

Initial acquisition of ISO9001

2015 Quality management system in 2010

Initial acquisition of IATF16949

16949:2016 Quality management system for automobile industry in 2010

Initial acquisition of AS 9100D

Quality management system for aerospace in 2019Initial acquisition of Nadcap

Heat Treating Special process certificate for international aerospace industry.