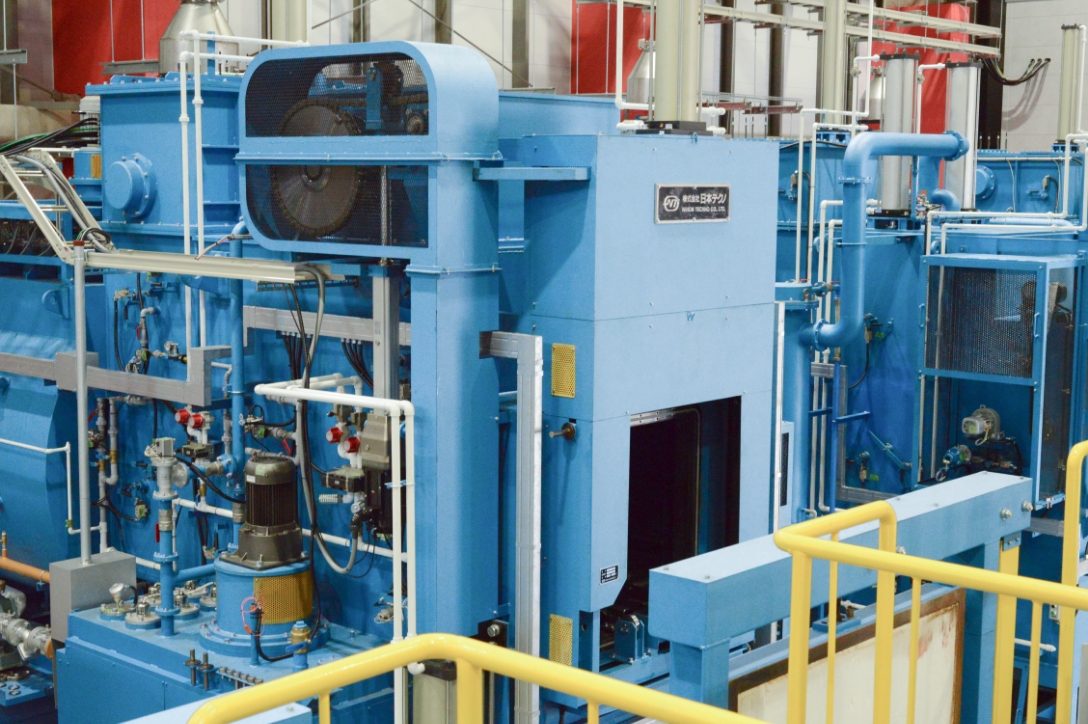

Tokyo South Factory

The South Factory is a 10-minute walk from the head office in Musashimurayama City. This plant features a state-of-the-art heat treatment furnace that enables heat treatment with low distortion and high sliding properties. It is also possible to carburize even hard-to-carburize parts.

With the mission of "supporting the foundation of the machinery industry," we will continue to meet various needs in the future.

What Tamayakin can do

What Tamayakin can do

Tokyo South Factory

The South Factory is a 10-minute walk from the head office in Musashimurayama City. This plant features a state-of-the-art heat treatment furnace that enables heat treatment with low distortion and high sliding properties. It is also possible to carburize even hard-to-carburize parts. With the mission of "supporting the foundation of the machinery industry," we will continue to meet various needs in the future.

State-of-the-art

heat treatment

The South Factory is a plant that is 20 years ahead of its time, utilizing state-of-the-art technology and capable of meeting the needs for higher precision. Like the main plant, it will handle small-lot production of a wide variety of products as well as mass production. In addition, machining and tool design and manufacturing are also planned.

We will propose the construction of a supply chain for integrated production of parts and process improvement.

Heat Treatment at Tama Metallurgy

quenching

Less distortion reduction and polishing allowance

A process in which nitrogen is solidly dissolved in place of carbon before quenching, which allows quenching at a lower strain than carburizing or carbonitriding.

Characteristics of Nitrocarburizing and Quenching

I want to harden with less distortion, but

Nitriding is not applicable without alloy steel.

By quenching with nitrogen infiltration

hardening can be performed with the same degree of strain control as nitriding.

hardening

Increase hardness with less distortion

Aiming for low distortion by controlling the optimum quenching rate with varying oscillation conditions.

Characteristics of Oscillatory Hardening

Any air bubbles between the oil and the product

can be a source of distortion.

Vibration is applied to

Cooling while removing air bubbles.

carburization

Carburizes even hard-to-carburize areas

A process that allows acetylene gas to adhere to the surface of a product and diffuse through osmosis the carbon in the acetylene gas on the surface of the product.

Features of Vacuum Carburization

Gas carburization.

Some areas could not be carburized.

Vacuum carburizing

Deep pore carburization is possible.

nitriding

improve sliding properties

A treatment in which a sulfurized layer is formed over a nitrided layer. The formation of a lubricating nitrocarburizing layer improves wear resistance, seizure resistance, galling resistance, fatigue resistance, corrosion resistance, and other properties.

Characteristics of immersion nitriding

Conventional gas nitrocarburizing

Low sliding properties.

A sulfide layer is formed on top of the

nitride compound layer

on top of the nitride layerto

enhance solid lubricity.

carburizing

and nitriding

Low distortion

Can be carburized/nitrided

Low temperature allows nitriding at a low temperature range that does not form chromium carbides and hardens without affecting the passive film and maintaining corrosion resistance.

Features of low-temperature carburizing and nitriding

I want to carburize/nitride but

I want to distort.

In low-temperature carburizing and nitriding

Carburizing and nitriding without distortion.

Features of Tokyo South Factory

Non-stop from machining

Machining and tool design and manufacturing will be implemented. We will propose the establishment of a supply chain for integrated production of parts and process improvement.

Suitable for mass production

The South Factory is equipped with facilities for mass production. We can meet various needs for automotive parts, aircraft parts, precision equipment, etc.

State-of-the-art technology for low distortion

We can heat treat to low distortion with state-of-the-art technologies such as nitrocarburizing quenching, carburizing-nitrocarburizing, vacuum carburizing, low-temperature carburizing, and low-temperature nitriding.Tokyo South Factory

Address 3-23-1 Inadaira, Musashimurayama-shi, Tokyo 208-0023 TEL: 042-560-4331 Fax: 042-560-4550

15 minutes by bus from Akishima Station on the JR Oume Line

Bus (Sho 22) IHI (via Estate Tachikawa)|8 min. walk from Inadaira-minami intersection

Bus (Sho 26) Harunadairazuka (via Estate Tachikawa)|8 minute walk from Inadaira-minami intersection

Bus (Sho 24) bound for Hakonegasaki Station East Exit|8 minutes walk from Inadaira-minami Intersection bus stop

Bus (Sho23) bound for AEON MALL: 8 minutes walk from Inadaira-minami Intersection bus stop.

All of the above buses can be boarded at the Seibu Haijima Line and Seibu Tachikawa Station entrance. *When taking the bus from Seibu Tachikawa Station, the bus does not stop in front of the station.

To get to the bus stop, walk along the railway line in the direction of Shinjuku for about 3 minutes.

1.5 km from Tennobashi intersection on Itsukaichi Kaido Road

650m from Matsunaka Danchi Minami intersection on Itsukaichi Kaido

4.9 km from JR Akishima Station

4.8 km from Seibu Haijima Station

2.5 km from Seibu-Tachikawa Station on the Seibu Line

2.2 km from Musashi Sunagawa Station on Seibu Line

10.4 km from Hachioji Interchange on Chuo Expressway via Haijima Bridge and Akishima

13.0 km from Iruma Interchange on Ken-O Expressway via Route 16 and Shin-Ome Kaido