Tamayakin’ initiative

Tamayakin’ initiative

Asphyxiation

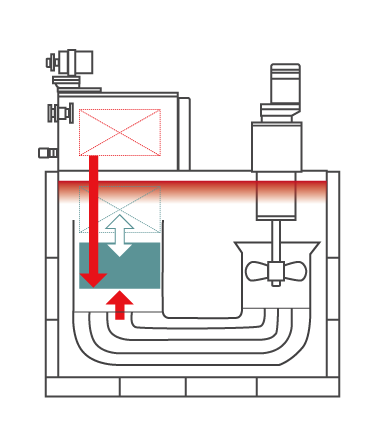

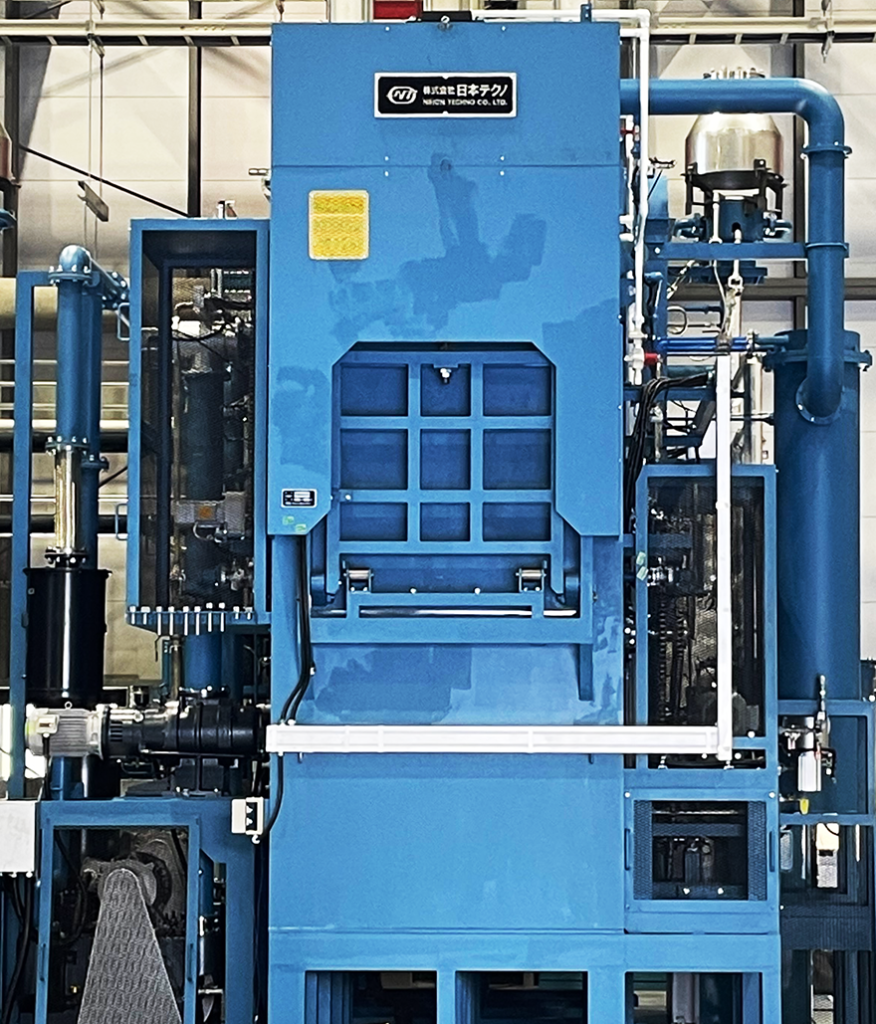

quenching

Return to list

Return to list

01 Characteristics and issues of surface treatment to date

Steel used for machine parts has been subjected to surface hardening heat treatment to improve friction resistance and fatigue strength.

Major surface hardening heat treatments include the following

| Main heat treatment methods | feature | issue | |

| Gas Carburizing Carburizing and nitriding |

Easy adjustment of carbon concentration. Stable quality. |

→directional marker or indicator | Reduction of quenching distortion |

| Nitriding Gas nitrocarburizing Ion nitriding |

Curing is possible with low distortion. | →directional marker or indicator | (Nitriding) Shorter processing time (Nitrocarburizing) Higher hardness |

| high-frequency quenching | Short processing time Reduced strain Easy to line up and automate |

→directional marker or indicator | Application of less expensive steel grades instead of specific steel grades |

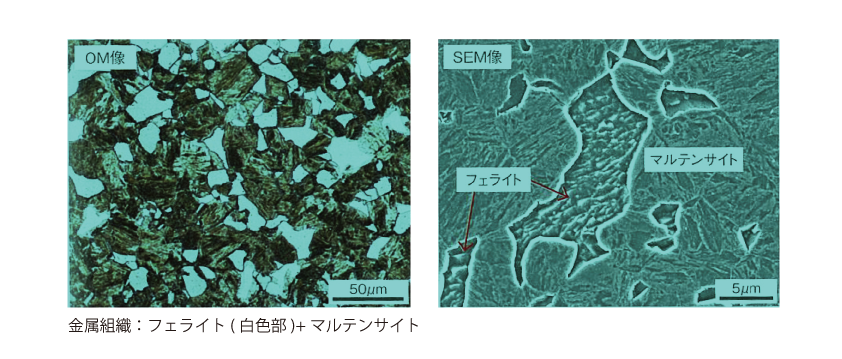

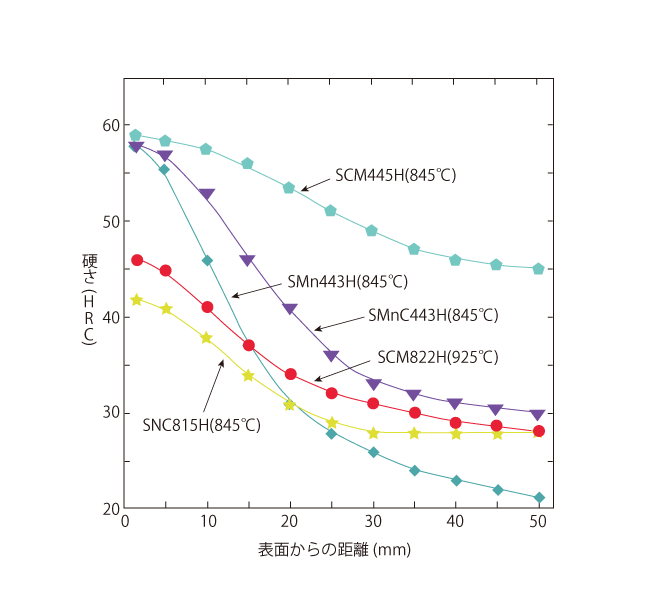

02 A new surface hardening heat treatment that solves the problem: Carburizing and Quenching

<1> BY PERFORMING QUENCHING WITH NITROGEN INFILTRATION, SURFACE HARDNESS OF ABOUT 850 HV CAN BE OBTAINED EVEN WITH INEXPENSIVE SPCC MATERIAL, AND HARDNESS CAN BE INCREASED TO THE EXTENT THAT NITROGEN DIFFUSES INTO THE INTERIOR.

<2>The amount of strain is about half that of carburizing and nitriding, and only slightly larger than that of gas nitrocarburizing.

<3>The coefficient of friction and quenched surface pressure are almost equal to those of carburizing-nitriding and gas-soft nitrocarburizing. The amount of wear is 1/2 that of carburizing-nitriding hardened materials and 1/3 that of gas soft-nitriding materials, which is good.

Since carbon-based gases are not utilized, the surface roughness of the sample after treatment is excellent.

Treatment time is 1/3 to 1/4 that of gas nitrocarburizing, a significant reduction.

Tempering softening resistance comparable to that of carburizing.

03 Distortion can be further reduced by low-temperature nitrocarburizing and quenching.

While nitriding can be applied only to alloy steels, low-temperature nitriding and quenching can be hardened without alloying elements, with distortion as small as that of nitriding.

A surface hardening layer of 900 Hv or more can be obtained.

Hardening by aging.

Unlike carburizing, there is no concern about sooting and the finished skin is good.

The cost can be cut compared to nitriding because surface hardening can be done even with inexpensive materials.

quenching