70 Years of History of

TAMAYAKIN (Foundation Period)

The history of 70 years of dedicated heat treatment is presented here.

70 Years of History of

TAMAYAKIN (Foundation Period)

70 years of history

dedicated to heat treatment

“Heat treatment” is a special processing technique that controls the strength and durability of a metal by adjusting the heating and cooling of the metal to make it soft or hard. The history of this technique is also deeply rooted in the culture of Japanese people, as it has been used for making Japanese traditional sword by smiths.

Today, it is widely recognized as a technology that is closely linked to the development of the economy and industry, from vehicles such as automobiles and aircraft to precision instruments and machining and in the field of aircraft, where high precision is required, this technology is particularly valued for its indispensability.

We are a group of professionals in the field of heat treatment, which has been growing with the development of the Japanese economy since 1951.

In the past, the company has experienced difficulties due to the economic downturn and natural disasters, but we are proud of the importance that heat treatment technology brings to the world and we are constantly improving our "technology, people and workplace".

With "Mission", "Vision", and "Spirit" at the core, we will continue to create the next day with daily inspiration and empathy to pass on technology, culture, and spirit to the next generation through people-to-people relationships.

Founding of TAMAYAKIN

Born in Tokyo in 1926, he graduated from Waseda University with a degree in science and engineering.

After graduating from Waseda University, he served as an engineer in the Navy.

At the end of the war, he started the previous company of TAMAYAKIN Co., Ltd. called Tama Heat Treatment Co. Limited. At that time, we built a heat treatment kiln by hand to heat treat automobile parts.

We strived to develop our technology in the era of rapid economic growth, and we developed our technology and company, creating the foundation of TAMAYAKIN.

From the very beginning of the company, my wife, the late Takako Yamada, took the background roles from accounting to delivery, working together closely to overcome the difficulties.

Kei Yamada and his wife Takako

Kei Yamada and his wife Takako

TAMAYAKIN History

From the postwar period to the present

and into the future We will introduce a history of TAMAYAKIN's challenges,

which have continued to support the world's industries.

Founding Period|1951~

"Supporting Postwar Reconstruction!"

Founder's Struggle

The company was founded in the chaos of post-war reconstruction and struggled to support Japan's manufacturing industry during the period of high economic growth.

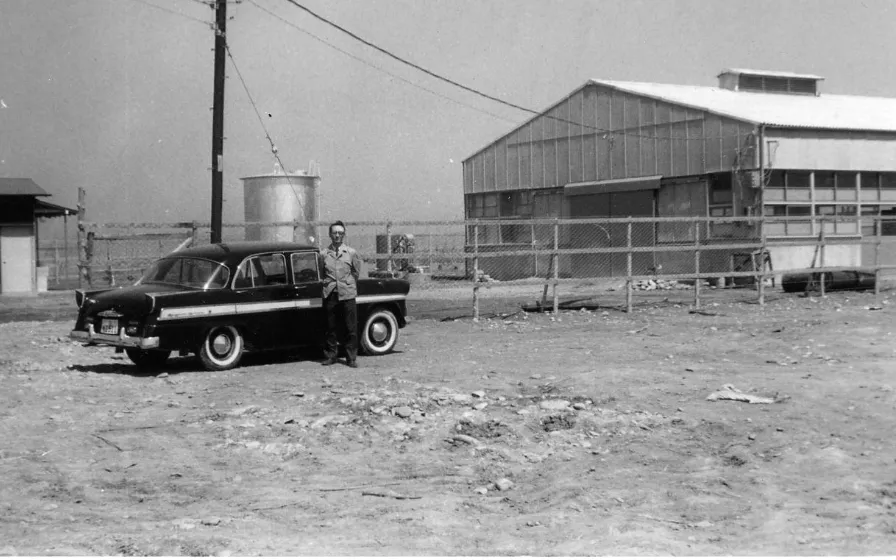

Tama Heat Treatment Co., Ltd. founded in Musashino City.

Kei Yamada, the founder of Tama Heat Treatment Co., Ltd. with a capital of 1,000,000 yen and starts business in Nakamachi, Musashino City, Tokyo.

Musashino Factory in its founding period

After graduating from Waseda University with a degree in engineering and applied chemistry, Kei Yamada went to work for Jilin Artificial Oil Co., Ltd. until he was called up as a Naval Engineer to work on gunpowder production at the Naval Arsenal during the Pacific War.

After the war, he used his knowledge of chemistry to start a heat treatment business in the abandoned factory owned by his father, Tama Insulators Ltd.

He laid the foundation for the business that would lead to the present.

At that time, Musashino City was home to a number of small factories where independent workers with superior technical skills could work under their individual initiative, following the dismantling of the Nakajima factory that manufactured engines for the Zero fighter and other military aircraft.

Due to the influence of this, the company started with the heat treatment of gingers and other parts, but the need for these parts quickly spread to include car parts and machine parts. During the confusion of the post-war period, the company transformed itself to support the manufacturing industry, which was the foundation for reconstruction.

Musashino Factory in its founding period

Musashino Factory in its founding period

Detail

Relocation due to housing development. Expanding its factory,

moving to Musashi-murayama city!

Musashino Factory in its founding period

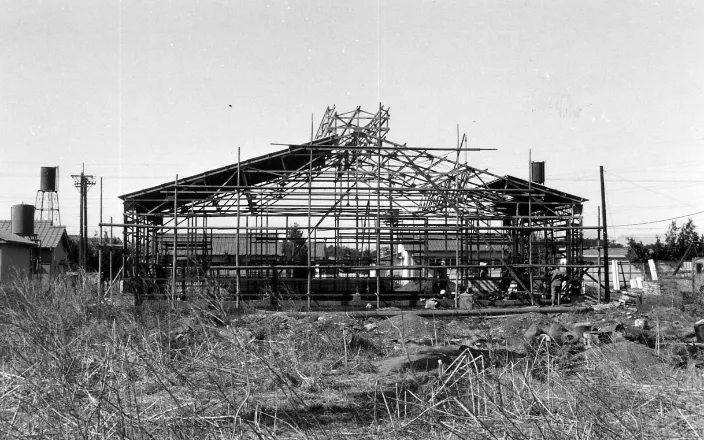

Scene of construction of the atmosphere factory

Scene of construction of the atmosphere factory

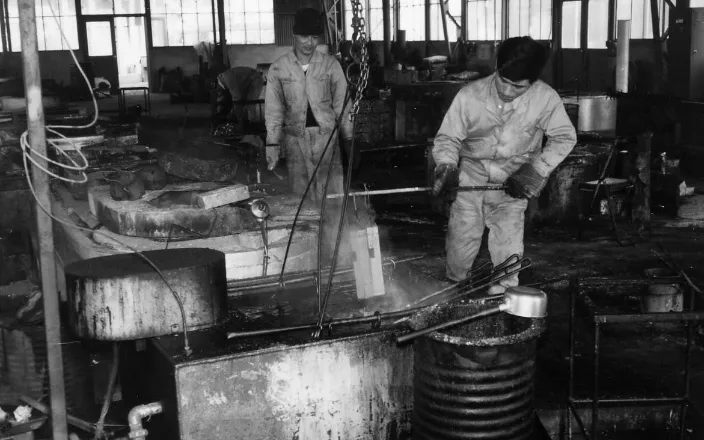

Scene of salt bath at work (Around 1965)

Scene of tempering work (around 1970)

Detail

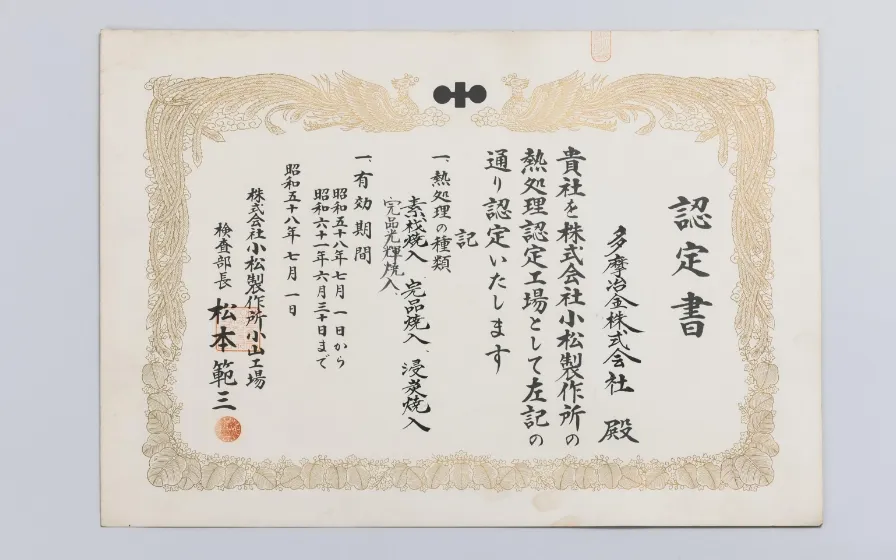

Participation in the auto industry, becoming a certified factory

Became an approved heat treatment factory for Nissan Diesel, Komatsu Manufacturing, Caterpillar Mitsubishi, etc.

Ltd. certificate at the time.

Company name change and the birth of TAMAYAKIN Co., Ltd.

The company name and organization were changed to TAMAYAKIN Co., Ltd. The wife of the founder, Takako Yamada, is also in charge of finance as the vice president, and the couple manages the company together.

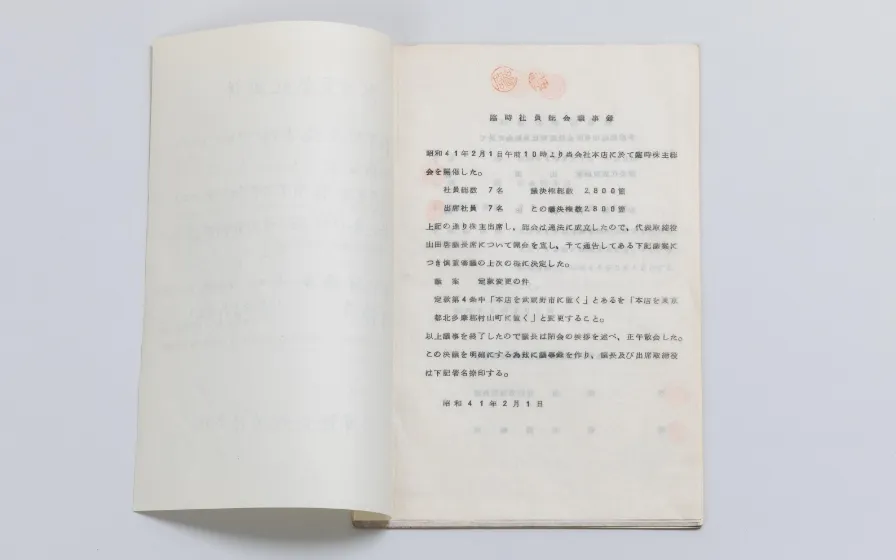

Articles of Association (1966), changed at the time of the move to the current Musashi Murayama City (then Murayama-cho, Kitatama-gun, Tokyo).

Challenge to other industries, small lot multi-product.

Shift from mass production of parts for automatic transmissions and construction machinery to small-lot multi-product production system of a wide variety of products across multiple industries.

Inspection area.

The factory was a subcontractor for a major car manufacturer and was approved by several companies, but as we entered a period of high economic growth, the demand for short delivery times and low prices for heat treatment became more severe. The founder of the company, Kei Hirata, thought that "subcontracting to large companies would not allow us to make the most of our strengths," and decided to shift to a small lot multi-product production system in order to provide high value-added services and establish a highly profitable management system.

Focusing on local customers rather than on mass-produced products from large companies, the company decided to make a capital investment to develop its internal structure with the phrase "from a single screw to highly complicated products". This attitude was one of the innovations that clearly showed the company's commitment to taking on the challenges of the times.

Construction of office building (completed in April 1982)

People in the founding period of the company

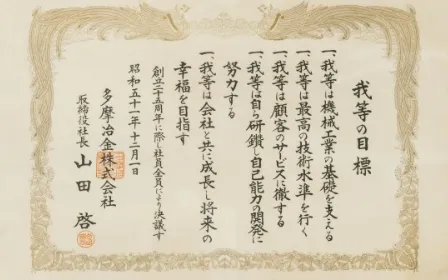

Our goal

Detail

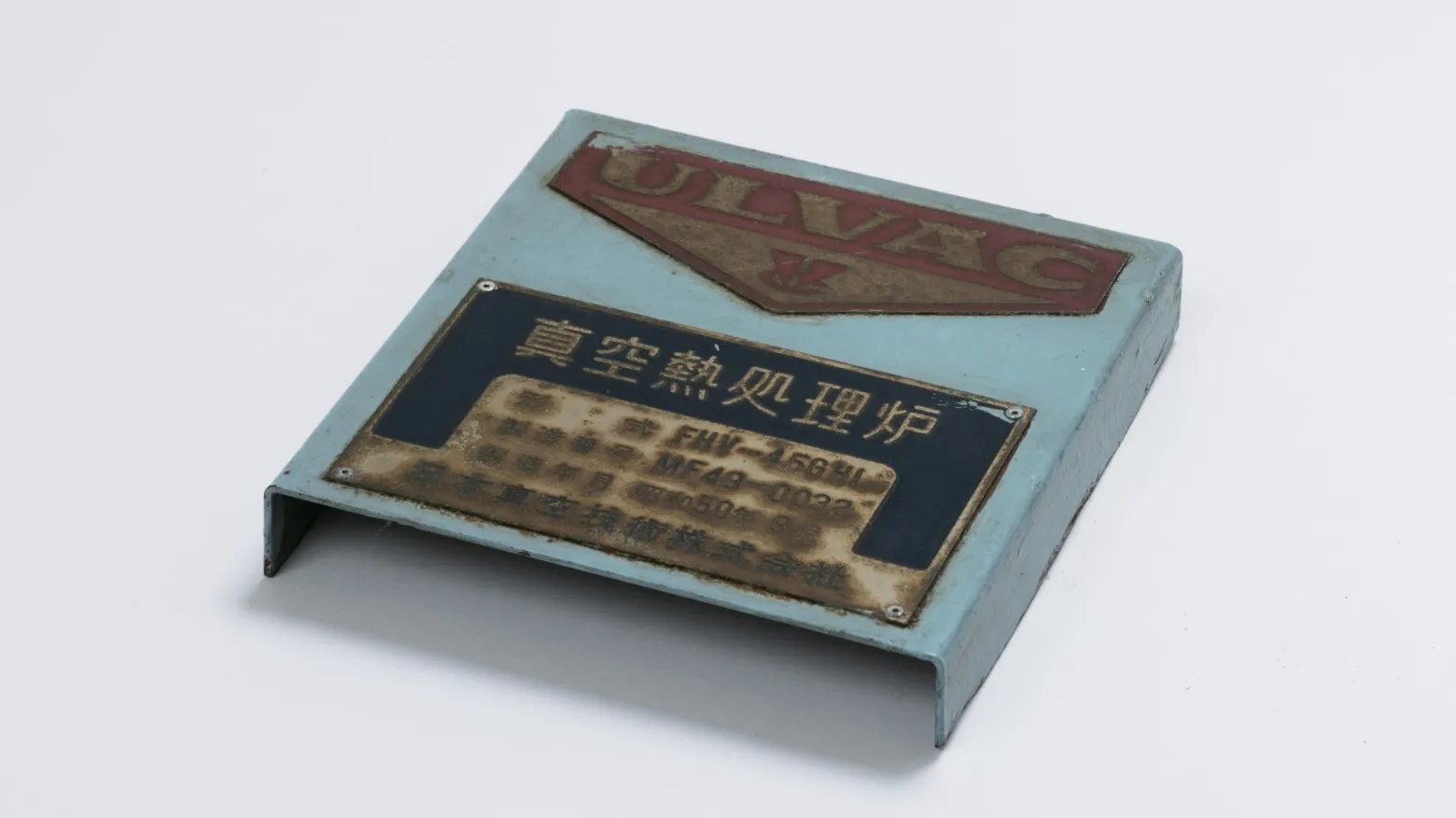

Aim for the highest technological standards and the introduction of vacuum furnaces.

Introduction of a vacuum heat treatment furnace. This marked the beginning of a shift to high value-added, precision parts production. Thereafter, new vacuum furnaces were installed.

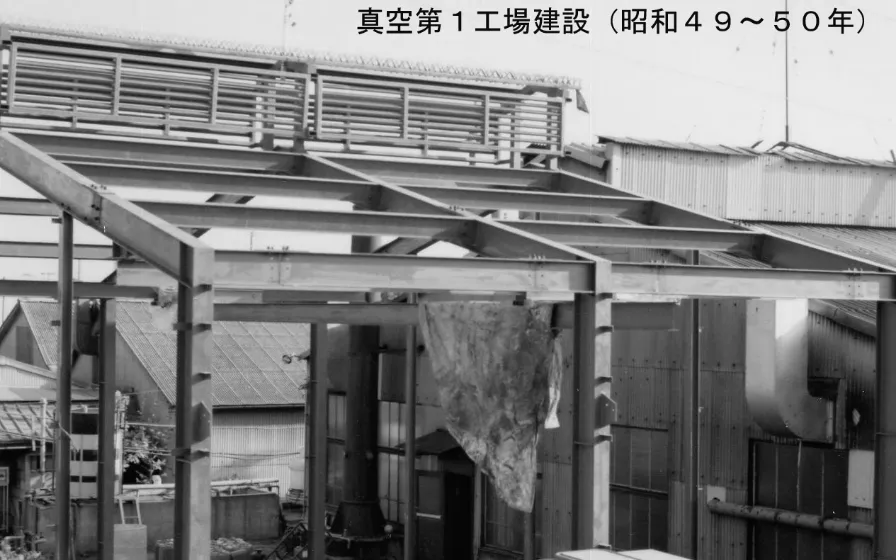

Construction of Vacuum Plant 1 (1974-1975).

The development of vacuum furnaces for industrial use has made it possible to use vacuum heat treatment for industrial purposes. At that time, vacuum furnaces were extremely expensive equipment, but Kei Yamada decided to adopt the most advanced technology and introduced the first vacuum furnace ahead of other companies in the industry. Vacuum heat treatment was suitable for heat treatment of molds and precision parts because it could be used at higher temperatures without oxidation. For the customers, it opened up a new field of manufacturing of molds and parts, which led to a flood of orders from a wide range of customers. Soon, it was not enough to install just one furnace, so the second and third furnaces were installed in succession. This gave the company the funds to make further advances, and at the same time demonstrated its clear value as the "TAMAYAKIN for small lot multi-product, high value-added heat treatment”.

Vacuum No. 1 installed (Oct 1975).

Vacuum 1 commissioning.

Detail

The road to further technological development and trial and error

An ion plating system was introduced to further enhance the production system.

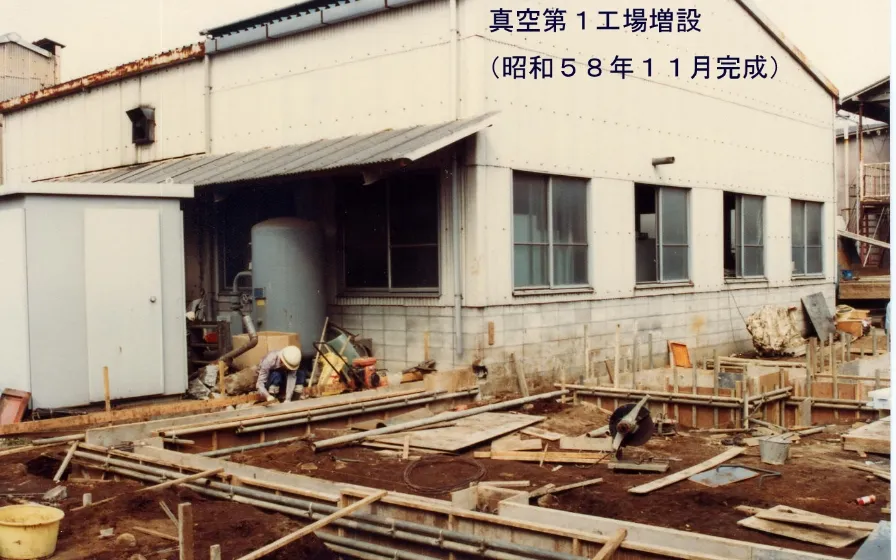

Added Vacuum Factory No. 1 (completed in November 1983)

Vacuum No. 3 installed (February 1984)

View of Vacuum Factory No. 1

Detail

First Growth Period|1988~

“Products that fly in the sky,

flying heat-treated products” Entry to the aircraft industry

It was a time of great change in the world, with the bursting of the bubble economy and digitalization.

TAMAYAKIN is now ready to take one step toward the aerospace industry.

Acquired the first heat treatment certification

Acquired heat treatment certification for aircraft engine parts (V2500) supplied to IHI (Ishikawajima‐Harima Heavy Industries, Co., Ltd.).

This could be the beginning of the development of a production system for MIL-standard products. Since then, we have acquired special process approvals for the following companies: Eagle EG&G Aerospace (MILH-6875), IHI Aerospace (Aluminum Alloy), and Nissan Auto (Aerospace Division, now IHI Aerospace (MIL-H-6875).

Hitoshi Yamada, the second generation president and former chairman, joined TAMAYAKIN in November 1987. From the very beginning of his career, he took advantage of his experience as a pilot in the Maritime Self-Defence Force and single-handedly took on the challenge of pioneering the aircraft industry with a passion for aeroplanes.

Entering the aircraft industry was in line with the company's direction of 'high added value in small lots of a wide variety of products', but on the other hand, the door itself was not open to companies that did not understand or have a production system suitable for such manufacturing. In the absence of an information network such as the internet, Hitoshi Yamada had to use all the methods he had developed in his previous job, including personal contacts and contacts, to "do the legwork" to obtain the necessary information on quality control, equipment management systems and human resources training.

He overcame a difficult situation with his high motivation for the aircraft industry and aeroplanes, and obtained heat treatment certification from IHI Corporation just under a year after joining the company. This first step, pioneered by Hitoshi Yamada, became the foundation of TAMAYAKIN's current strength in the aircraft industry, and was passed on to the third president, Takeshi Yamada.

Detail

Accepting Trainees from China

One or two young engineers from China come to Japan every year for a year-long training period to learn about Japanese heat treatment. One or two young engineers from China come to Japan every year for a year-long training period to learn about Japanese heat treatment.

For the past 11 years, we have trained a total of 16 young Chinese engineers.

Three of them came to Japan again and have been working as employees ever since. They sent us human resources who had graduated from one of the best universities in China and had majored in heat treatment and metals.

First trainees, commemorative photo on the day of their first visit to Japan

Hitoshi Yamada (1st left) and Mr Sato (3rd left), General Manager of the General Affairs Group, flank the first batch of trainees (2nd left: Zhu, 4th left: White) at the Academic Hall.

Selection of technology that considers the natural environment

Introduced a water-based vacuum cleaner to eliminate the use of chlorinated organic solvents, which are ozone-depleting substances.

SECOND HYDROCARBON VACUUM CLEANER VW2 INTRODUCED.

Appointment of second president,

Heat treatment aimed at pilots

The second president, Hitoshi Yamada, who had served as a pilot in the Maritime Self Defense Force, became the president. In the same year, his colleague from the Self-Defense Force, Hajime Mamiya was appointed as the head of the factory.

The second president (right) and plant manager (left) who led the pioneering work

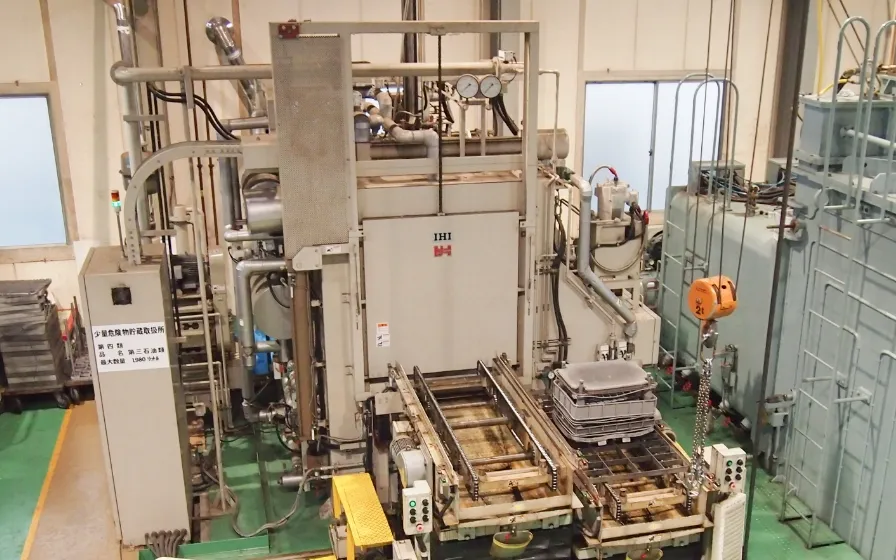

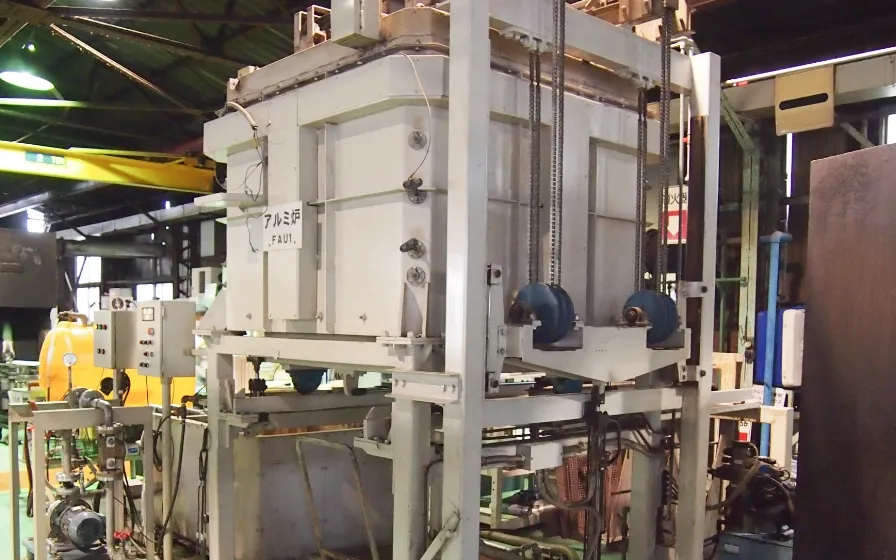

Installed a heat treatment furnace for aluminum alloy for aircraft.

Installed a heat treatment furnace for aluminum alloy for aircraft. Started heat treatment of aluminum parts for aircraft.

Aluminium furnace No 1. With the introduction of this equipment, aluminium alloys can now be solution-treated.

Further certification, further aircraft parts, Further heat treatment

The company obtained special process (P-2020) certification for special processing at the Nagoya Aerospace Systems Works of Mitsubishi Industries, Ltd. and special process (MIL-H-6088) at Utsunomiya Works of Fuji Heavy Industries, Ltd.

Acquisition of ISO 9001 certification and organizational structure for quality

Acquired ISO9001 certification.

THE THEN STATE-OF-THE-ART VACUUM 8 FURNACE, INTRODUCED AT THE SAME TIME AS THE ISO 9001 CERTIFICATION, BEING BROUGHT IN.

Digitalisation has enabled

a high-mix, small-lot production system.

Upgrade work order system software to improve reliability.

Screen of the process progress system, which was revolutionary at the time and was interviewed.

THE FOUNDER OF TAMAYAKIN HAS BEEN ACTIVELY INVOLVED IN TRACKING SYSTEMS, WHICH ARE NOW THE STANDARD, SINCE THE DAWN OF IT, AND IN 2001, THE INFRASTRUCTURE WAS FURTHER IMPROVED AND THE SYSTEM WAS MODIFIED TO AUTOMATE TEMPERATURE INSTRUCTIONS IN THE HEAT TREATMENT PROCESS BY QUANTIFYING CRAFTSMANSHIP, THEREBY SAVING LABOUR IN HANDLING SMALL LOTS OF VARIOUS PRODUCTS. THE SYSTEM HAS ALSO MADE THE CONTROL SYSTEM OF THE HEAT TREATMENT EQUIPMENT MORE LABOUR-SAVING. IN ADDITION, THE CONTROL SYSTEM FOR THE HEAT TREATMENT EQUIPMENT WAS RENOVATED IN-HOUSE, AN EQUIPMENT MANAGEMENT SYSTEM WAS BUILT AND IT TECHNOLOGY WAS INCORPORATED TO THE MAXIMUM EXTENT POSSIBLE IN THE RECORDING OF HEAT TREATMENT PROCESSES, THEREBY IMPROVING THE RELIABILITY OF HEAT TREATMENT, OR 'SPECIAL PROCESSES', WHOSE QUALITY IS DIFFICULT TO JUDGE FROM THE FINISHED PRODUCT. THE COMPANY'S PURSUIT OF "BETTER SERVICE FOR CUSTOMERS" AND ITS ATTITUDE OF TRYING TO SOLVE PROBLEMS WITH TECHNOLOGY WITHOUT FEAR OF REFORM IS ALSO AN EXPRESSION OF "TAMAYAKIN'S CHARACTER".

Detail

Started to receive orders for Defense Components.

The company has acquired the certification of the special processing of Sumitomo Heavy Industries Ltd. special process (MIL-H-6875) and started the heat treatment of the Ministry of Defense equipment.

Expansion into the northeastern part of China in the city of Dalian ,supporting the foundation of the machining industry.

Established TAMAYAKIN (Dalian) Co., Ltd." in Dalian, China and started the contract heat treatment processing business in China.

Total site area: 13,000m2. Capital: 260 million yen (increased to 340 million yen in 2007)

At that time, there was a lack of heat treatment industry both in number and quality in this area, which was needed for the development of the local machining industry. Particularly, the company provided high-quality heat treatment services to Japanese manufacturers in Dalian, contributing greatly to the localization of their production.

Dalian plant established (July 2003).

With the hollowing out of the manufacturing industry in Japan becoming an issue, TAMAYAKIN decided to expand into China in preparation for the further deterioration of the situation. Around the same time, I was approached by a previous trainee and we decided to proceed with preliminary research for a site visit and exhibition in Shanghai. In the process, we found that many companies, especially Japanese companies with their own factories in Dalian, had expressed a strong desire to have an industrial heat treatment factory in the city. We have realized many complaints there are no suitable heat treatment facilities in the area and also that there are high expectations for TAMAYAKIN. Based on the results of feasibility studies, etc. we decided that the city of Dalian would be a good match for us in terms of size, rather than a large city, then we have set up a heat treatment factory in Dalian with high expectations from many companies. Since then, with the focus on the Japanese auto industry, the business in Dalian has been growing steadily as a base for transmitting "Japanese heat treatment" from China to other countries and the size of the factory has continued to increase.

Witnessing the opening ceremony of the Dalian plant, the future general manager of the plant.

- Bai and Jin Yamada, 2nd generation

Dalian factory construction site

Dalian factory construction site

The first step taken by Dalian factory was the heat treatment of the metal molds used to cast the parts, rather than the heat treatment of parts, which was the main focus of the head office. At that time, there were no heat treatment factories in the north-eastern area, including the city of Dalian, that were advanced enough to exploit the potential of the materials, so not only parts manufacturers but also steel manufacturers were looking forward to TAMAYAKIN for help. We received top-class technical training from a major manufacturer in the industry, even though we had no expertise in the field of metal mold heat treatment and the company has grown to handle a wide range of products, from small press metal molds for casting stainless steel and steel products used in daily life, to plastic molds for casting plastic and rubber products, to technically difficult die-cast metal molds weighing up to one ton. It was a time when the foundation was steadily being built while receiving a lot of expectations and cooperation.

Facilities in Dalian factory

Facilities in Dalian factory

Detail

Dalian factory moves from small-lot multi-product to mass production of parts

Auto parts, construction machinery parts, electrical parts, activities in the global field

View of the Dalian plant, which has a large site.

Dalian's main mass production results

The factory became a certified factory for heat treatment of metal molds for Hitachi Metals, Ltd., Kyoritsu Seiki (Dalian) Co., Ltd. (Head office Kyoritsu Seiki Co., Ltd.

Heat treatment of die-cast metal molds started.

Started to heat treat of the breaker parts for Fuji Electric Dalian Co. (Head office Fuji Electric FA Components & Systems Co., Ltd.)

Dalian Lin Precision Casting, started heat treatment of ABB's lost wax electrical components

RYOBI Pressure Casting Dalian Co. (Head office RYOBI LIMITED), Started heat treatment of die-cast metal molds and automobile engine blocks and in-line heat treatment of aluminum die-cast parts.

Detail

Dalian factory started mass production of electrical, electronic and mechanical components.

It was also true that the company could not expect significant growth. Seeing this situation, representative Pak decided to enter a new field. Finally, the company would start working on the heat treatment of parts, which is the main focus of the Tokyo Head Office. At that time, the quality of heat treatment technology in China was so low that manufacturers had to ship their products either in-house or to a factory in a city several kilometers away. Because of this background, the number of orders received increased rapidly in this area as well. With a focus on electronic, electrical, and mechanical parts, we decided to build a new era by accepting orders for heat treatment of a wide range of mass-produced parts. This was the beginning of a new stage in the development of TAMAYAKIN's products based on the know-how cultivated over many years at the Tokyo Head Office.

Dalian's main mass production results

Introduced carburizing and atmospheric hardening and started mass production of parts (Mike, Star Micronics, ABB)

Heat treatment of motor cases for locomotives at Dalian Toshiba Machine and Electrical Equipment Co.(Head Office Toshiba Corporation)

Started heat treatment of ball screw parts for Shenyang NSK Precision Equipment Co. (Head Office NSK Ltd.)

Detail

Pioneering Period |2004~

"Going into the Aviation Industry!"

The Struggle of the Third President.

It was a time when the company grew both in name and reality as Tama MAMAYAKIN in the aviation industry, hand in hand with the top companies in the industry, thanks to the skills of the third president, who has been engaged in sales activities as a senior managing director since 2004.

Acquired ISO14001 certification

Acquired ISO14001 certification

Recovering from the Lehman Shock, and Getting into the Airlines Industry.

The new factory for the heat treatment of aircraft parts was built on the site of a former salt bath.

Factory No.1

In order to enter a new era, we discontinued the salt bath heat treatment process that had been in operation since our foundation. Secured a place to set up a system to meet the needs of the industry at an early stage. The decision was made to build a heat treatment facility which has been gradually arranged for the next generation of main aircraft parts on the former salt bath site since 2011. Since then, the new factory has been used to produce engine and control components for new passenger aircraft.

The dismantling of the salt bath factory(2007)

Musashino Plant

Detail

Became a founding member of the technology collective "AMATERAS”.

As a founding member of the "Amaterasu" technology collective, we began consortium activities for the production of aircraft parts.

Amaterasu logo

"AMATERAS" is a "consortium of aerospace component manufacturing companies" with advanced technology in the Tokyo area, initiated by Tokyo as a corporate unit that will play a leading role in the next generation of the aerospace industry.

When the project began as a study group, as many as 300 to 400 companies participated, and 10 of them were selected as members of the AMATERAS unit.

TAMAYAKIN was selected as one of the best in the heat treatment division, among many leading companies in the industry, and made a new start as one of the leading members of the aerospace industry.

Through these activities, TAMAYAKIN has built a strong network of contacts and networks that it has never had before. Since then, through various encounters, we have steered the company to acquire JIS Q 9100 certification and Nadcap, and have been steadily advancing as a core company in the aviation industry.

Detail

Dalian Factory establishes mass production system for auto parts and makes a leap forward.

Dalian No. 2 plant equipment delivered.

Began heat treatment of auto parts for Dalian Gifu Kato Precision Processing Co. (Head office, Gifu Kato Manufacturing Corporation) AISIN AW Co.,Ltd.

Began heat treatment of auto parts for Dalian Precision Electronics Co. (Head office: Seiko Instruments Inc.)

Acquired ISO1400.

Acquired TS16949 (later IATF16949) certification.

Established a heat treatment department in the factory of Ryobi Pressing & Casting Dalian Co.

Began heat treatment of LM guide parts for THK Liaoning Precision Industry Co. (Head Office THK Co., Ltd.)

TAMAYAKIN (Dalian) Changzhou Branch Office was established in Changzhou, Jiangsu Province, started in-line heat treatment of die-cast aluminum parts for automatic car models at RYOBI Pressure Casting Changzhou Co. the head office of (Ryobi Co.).

In addition to heat treatment of moulds and electronic, electrical and mechanical parts, since 2009 the Dalian plant has also been involved in the heat treatment of automotive parts, which are also highly challenging in terms of quality assurance management. In fact, here, too, the strong expectations and support from the major manufacturers have been the catalyst for a new step forward.

Thereafter, in 2010, the plant acquired the international quality management standard TS16949 (later IATF16949) for the automotive industry, and entered the automotive industry in earnest. At the same time, the number of cars manufactured in China is growing rapidly, and the increase in demand for TAMAY metallurgy follows the same curve and steadily expands until 2017, when the annual domestic production of 29.94 million vehicles was recorded. This was a time when the Dalian plant built a solid foundation along with the development of the Chinese economy.

A second plant completed within five years of the opening of the Dalian plant.

A second plant completed within five years of the opening of the Dalian plant.

Detail

Go to the top, aircraft parts.

The path to heat treatment certification

It was not an easy road when entering the aerospace industry, with many major changes required.

The sunrise of the aircraft industry for our company began with the crisis of the Lehman Brothers collapse.

Acquired JIS Q Certification.

Acquired JIS Q Certification.

Introduced the latest equipment for heat treatment of aircraft parts.

State-of-the-art German and US-made equipment introduced with the aim of entering the commercial aircraft component market.

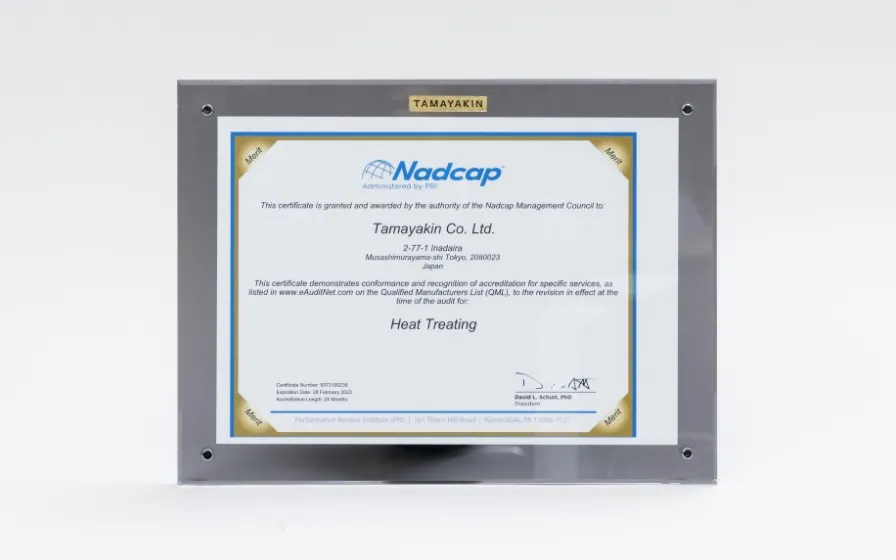

Acquired Nadcap certification.

Nadcap certification

Mass production of parts for aircraft engine PW1100G started.

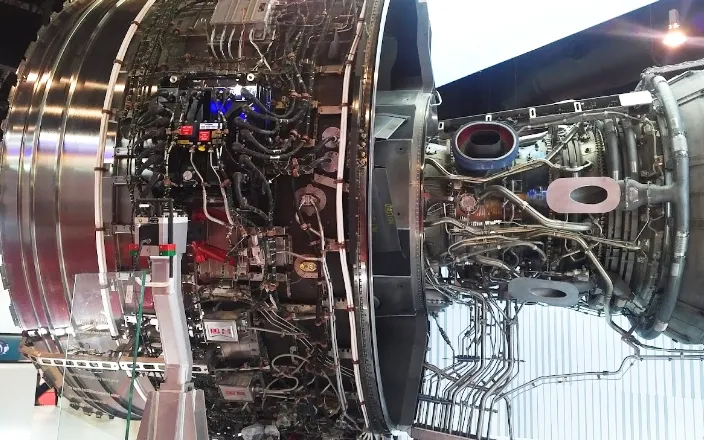

The PW1100G engine for the A320 neo, which has been ordered for volume production.

Rolls-Royce aircraft engine Trent XWB, for which heat treatment has been contracted since 2017

Packed products being shipped by large trucks.

Detail

Toward a system to increase production of aircraft engine PW1100G

Hiroshima Business Office opened.

Hiroshima Office, entrance signboard.

"JIS Q 9100", an international standard for quality management systems specialized in the aerospace and defense industries, has been adopted as a global standard for parts procurement by the aerospace and defense industries around the world. This is a management system standard for ensuring the safety and improving the reliability of products and services in the aerospace and defense industries. Since it is extremely difficult to acquire such certification, only a few companies in Japan were initially certified. In this situation, TAMAYAKIN will continue to focus on all aspects of the innovation process, including strengthening the internal organization, making business processes more visible and ensuring compliance with the requirements of the JIS Q 9100 quality management system and the Nadcap international process certification program for the aerospace industry. On the other hand, it was not easy to break away from the "factory in the town" and the employees began to voice their opposition to the idea of working in a different way, but this gradually changed to a sense of challenging the company to do a job that no one else could do, fostering professional pride, dignity and strong teamwork.

Detail

Acquired heat treatment certification for Rolls-Royce.

Certified for heat treatment by Rolls-Royce.

Rolls-Royce heat treatment certification.

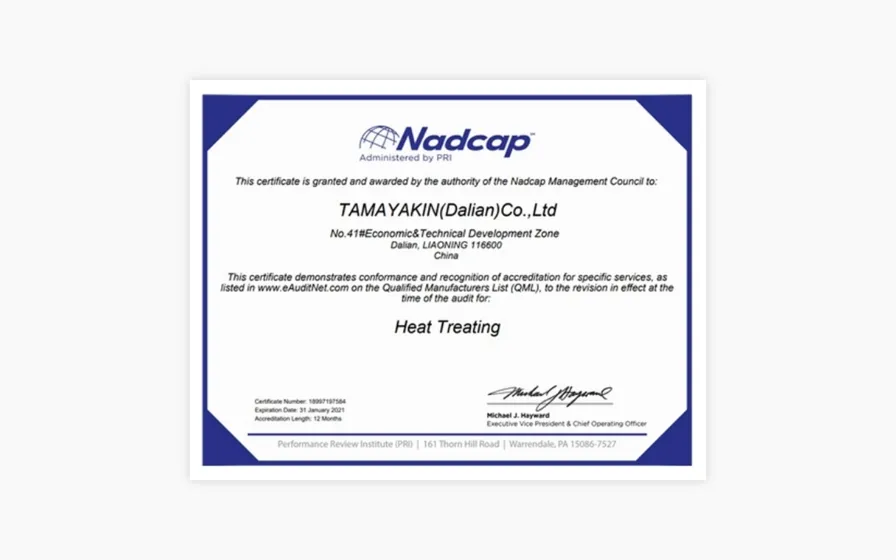

Acquired Nadcap certification at Dalian factory.

Acquired Nadcap certification at Dalian factory.

Nadcap accreditation of the Dalian plant.

The main focus of the Dalian factory continues to be the manufacture of auto body parts and while the factory is continuously investing in equipment, the path chosen by the representative Mr. Pak as a starting point for the next era is the aerospace field, which the Tokyo head office has already achieved the results. In 2019, they successfully acquired AS9100 certification, which is comparable to JIS Q 9100, which is considered difficult to acquire even in Japan, followed by NADCAP certification in the following year. Everyone at the Tokyo Head Office could not hide their surprise at the rapid progress made in such a short period of time. Although domestic demand is the mainstream for auto parts, the needs for aircraft are expanding globally. At present there is only a small amount of work on the aircraft equipment orders, but we are confident that this one step will open up a new chapter in the history of the Dalian factory's possibility.

Acquiring advanced certifications and contributing to local industries.

Acquired ISO9001

Acquired ISO1400.

Acquired IATF16949

Acquired AS9100

Acquired Nadcap.

Detail

Second Growth Period |2016~

'Aim for 100 years of enterprise!'

Manufacturing for the next generation of third generation brothers

Through the skills of the third president, who has been engaged in sales and marketing activities as managing director since 2004, the company

A time when the company grew as Tama Metallurgy in the aviation industry, both in name and in reality, hand in hand with the top companies in the industry.

First year of recruiting new graduates

Newly recruited students, the first group of employees entered the company.

Induction ceremony for new university graduates for the first time since the company was founded

Inauguration of the third-generation president, aiming to become a 100-year company with brothers.

Tsuyoshi Yamada, the third-generation President, took the post of President.

His younger brother, Shinsuke Yamada, was appointed as Vice President. Both of them started their careers with the aim of becoming a 100 year old company, TAMAYAKIN, using their overseas experience and backgrounds.

65th anniversary

Tsuyoshi Yamada, who took over as the third-generation president of the company on August 2017, utilized his experience as an expatriate in China during his previous career and demonstrated his ability to manage the company. Since he was a child, he had grown up watching the back of his father, Hitoshi Yamada, the current chairman of the company, and his interest in business was the strongest of all, so he wanted to join a small-to-medium sized company instead of a large company.

Detail

Construction of the South Factory

Just a 10 minute walk from the main factory in Tokyo, the company acquired a plot of land to continue and expand the business and the biggest South Factory in TAMAYAKIN started to be built considering for the next 20 years.

South Plant under construction (as it will look in January 2022).

With 'TAMAYAKIN' on the verge of becoming a '100-year company', the third-generation president is looking to 'the future beyond that'. And the newly built South Plant has an important role to play in laying the foundations for this.

Firstly, the plant aims to become a plant that is involved not only in heat treatment, but also in all product processes. This will establish a new business line, with heat treatment at its core, capable of handling everything from materials to final form.

Second, the plant will support the manufacturing industry of the future, which has yet to be seen. The plant aims to support the manufacturing industry on an unprecedented scale, including the new 'flying car', wind power generation, medical care and the environment, in addition to selecting equipment with a view to an era in which carbon neutrality will become mainstream. The story of TAMAYAKIN, as envisioned by the third president, is about to begin.

Plans for the completion of the South Plant.

Detail