Tamayakin’ initiative

Tamayakin’ initiative

Return to list

Return to list

Overview.

Hydrogen sensor enables control of the thickness of the compound layer

01 Aerospace response (Nadcap)

Of the companies in Japan that have received Nadcap certification for heat treatment, a total of six specialise in heat treatment, including our company. We have the largest number of certified heat treatment processes among them, with 11. (as of 10.11.2021).

02 Stainless steel can also be nitrided.

Alkaline cleaning and blasting are carried out as required, and grades of steel that are difficult to nitride, such as stainless steel, are also available.

03 Nitriding treatment can be selected.

Atmospheric nitriding with ammonia gas is carried out. Gas nitriding and gas nitrocarburising are available.

04 Surface hardening treatment to prevent thermal distortion.

Due to the low-temperature treatment, deformation is reduced and the product is highly resistant to wear and corrosion.

05 Gas nitriding treatment is also available for aerospace components.

The white layer is processed in a controlled manner.

06 Nitrided layers can also be measured by histological examination.

Precise measurements such as histological examination and internal hardness distribution are available.

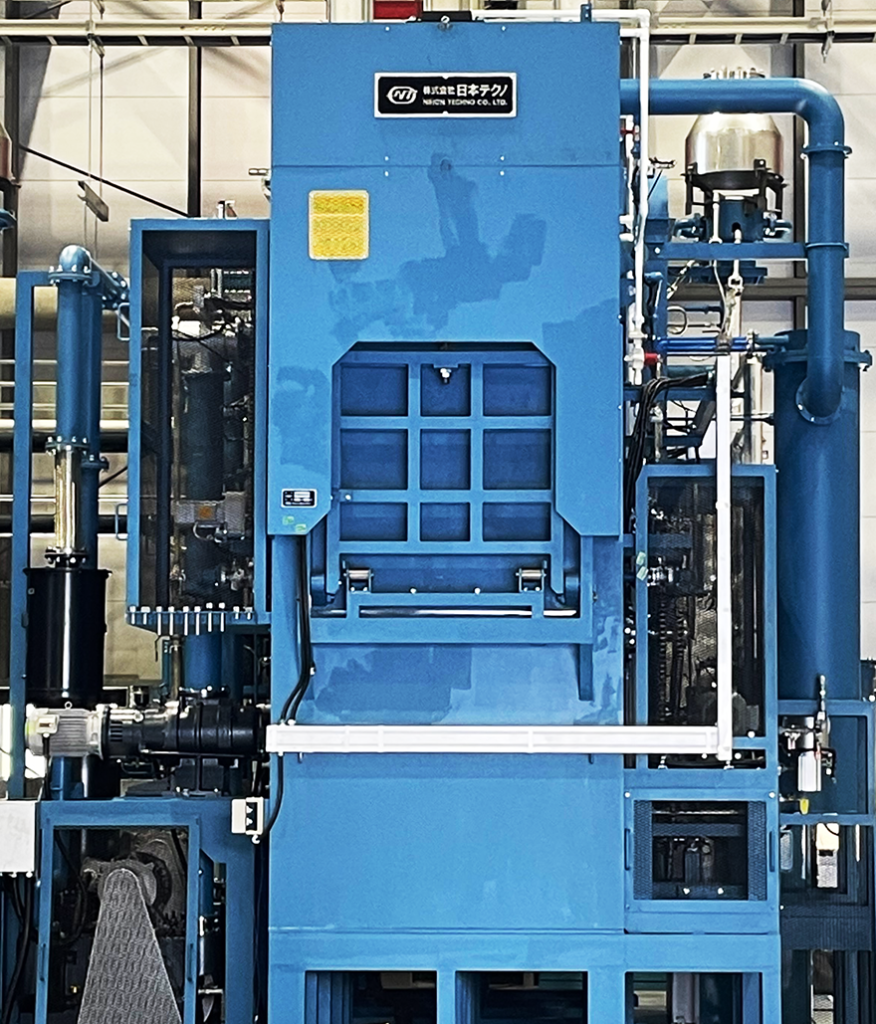

07 List of nitriding furnaces

| Equipment No. | working zone | Approved temperature range | Applicable specifications |

|---|---|---|---|

| FCN1 | Φ580 X 1030H | 0~600°C | |

| FCN3 | Φ590 X 1210H | 0~600°C | |

| FCN4 | 600W X 900L X 600H | 400~600°C | AMS2750, AMS2759, AMS2759/6, AMS2759/10, RRP54000, P11TF20 |

| FCN5 | Φ1050 X 1500H | 400~600°C | AMS2750, AMS2759, AMS2759/6, RRP54000. |