Japan Tokyo Plant

TAMAYAKIN Co., Ltd. (HQ) is located at Musashimurayama City, Tama District of Tokyo. The main feature of this plant is its capacity to offer heat treatment services in different volumes from single item to mass production using extensive treatment methods.

We will continue to fulfil our clients’ various needs and requests to “support the basis of the machine industry” as our mission.

What Tamayakin can do

What Tamayakin can do

Japan Tokyo Plant

TAMAYAKIN Co., Ltd. (HQ) is located at Musashimurayama City, Tama District of Tokyo. The main feature of this plant is its capacity to offer heat treatment services in different volumes from single item to mass production using extensive treatment methods.

We will continue to fulfil our clients’ various needs and requests to “support the basis of the machine industry” as our mission.

Quick delivery, airline, mass production system

Tamayakin is a heat treatment company independent from any particular corporations or industries. In addition, the company has established “multiproduct small-lot production system” to accommodate flexibly our clients’ various needs. This way, we have expanded the scope of our business activities over the years.

Today, Tamayakin is contributing to the business development of companies in main industries, including aviation, space, and defense, as well as precision machinery, electric components, and racing car accessories manufacturers.

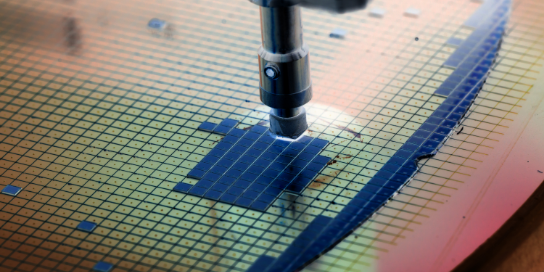

Heat treatment services offered at the Tokyo headquarters plant Heat treatment at TAMAYAKIN

Major certificates acquired from external agencies

Tamayakin is one of Japan’s leading Nadcap-certified companies specializing

in heat treatment.

Acquired 1999

ISO 9001 quality management system

Obtained in 2009

JIS Q 9100 Quality management system for aerospace

Obtained in 2012

Nadcap International Aerospace Industry Special Process Certification

Obtained in 2016

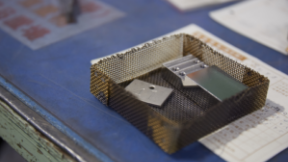

Heat treatment of Rolls-Royce engine components

Features of the Japan Tokyo plant

Production system capable of fulfilling orders as small as “a single item for next day delivery”.

Tamayakin has worked on for a long time to establish “multi-products/short delivery/small-lot production system” that enables to flexibly fulfill the diversified needs of the clients.In addition, for the clients’ peace of mind and satisfaction, we offer consolidated service, “AINORI”, in which the furnace is operated periodically on the heat treatment condition that fulfills the most frequent needs to serve multiple clients.

Place an order online wherever you are in Japan

We have online order system available for clients’ peace of mind. The clients are able to check the degree of process online. After the heat treatment work is complete, the products will be shipped to each client anywhere in Japan. We also give technical consultation over the phone.

The company acquired the only international certificate program associated with the aerospace defense industry.

Tamayakin is one of a few heat treatment suppliers in Japan that fulfill aircraft manufacturing specifications. It can accommodate any heat treatment needs with its solid technological ability that is recognized by third-party organizations.・The company acquired JIS Q 9100 in 2009 (Examination authority: BSK)

・The company acquired the special process certificate for civilian aircraft parts.

The company acquired “Nadcap” in 2012.

・The company acquired Rolls-Royce certificate for engine parts heat treatment process confirmation in 2016.

Japan Tokyo Plant

Address. 2-77-1 Inadaira, Musashimurayama-shi, Tokyo 208-0023 TEL: 042-560-4331 Fax: 042-560-4550

15 minutes by bus from Akishima Station on the JR Oume Line.

Bus (Sho 22) IHI (via Estate Tachikawa)

Bus (Sho 26) Harunazuka (via Estate Tachikawa), 3-minute walk from Inadaira-minami intersection.

Bus (Sho 24) bound for Hakonegasaki Station East Exit, 1 minute walk from Murayama Heights-mae bus stop.

1-minute walk from Murayama Heights-mae bus stop.

All of the above buses can be taken at the Seibu Haijima Line and Seibu Tachikawa Station entrance.

*When taking the bus from Seibu Tachikawa Station, the bus does not stop in front of the station.

Walk along the railway line to the bus stop in the direction of Shinjuku for about 3 minutes.

1.5km from Tennobashi intersection, Itsukaichi Kaido Road

1.2km from Matsunaka-danchi-minami intersection on Itsukaichi Kaido Road.

4.0 km from JR Akishima Station

4.8 km from Seibu Haijima Station.

1.8 km from Seibu Tachikawa Station on the Seibu Line.

2.3 km from Musashisunagawa Station on the Seibu Line.

9.6 km from Hachioji Interchange on the Chuo Expressway via Haijima Bridge and Akishima.

10.0 km from Iruma Interchange on Ken-O Expressway via Route 16 and Shin-Ome Kaido.