Tamayakin’ initiative

Tamayakin’ initiative

spheroidization annealing

Return to list

Return to list

Overview.

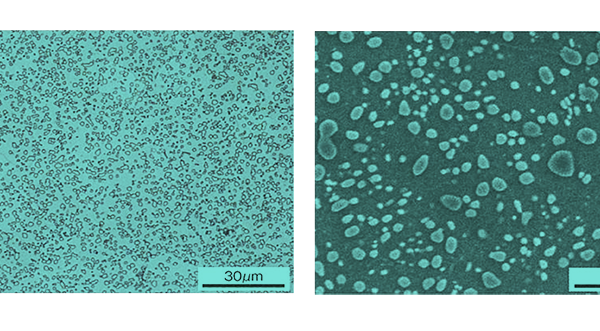

Spheroidizing annealing is a treatment to spheroidize layered cementite (Fe3C) and is an essential heat treatment for carbon tool steel (SK), alloy tool steel (SKS) and bearing steel (SUJ).

01 Purpose of processing

Spheroidizing and Annealing of Steel for Machine Structural Use Spheroidizing Annealing to machine structural steels is to to improve plastic workability and toughness and toughness. For this reason, spheroidizing annealed materials are inevitably used for bolts that are cold-headed and for structural parts that are cold-forged.

When tool steel and bearing steel are fully annealed, a large amount of layered thin-plate Fe3C is formed, resulting in poor machinability. Furthermore, such thin-plate Fe3C tends to be excessively solubilized by quenching compared to spherical Fe3C, resulting in weak mechanical properties after quenching and tempering. Therefore, tool steels and bearing steels are always commercially available with spheroidizing annealing.

02 annealing method

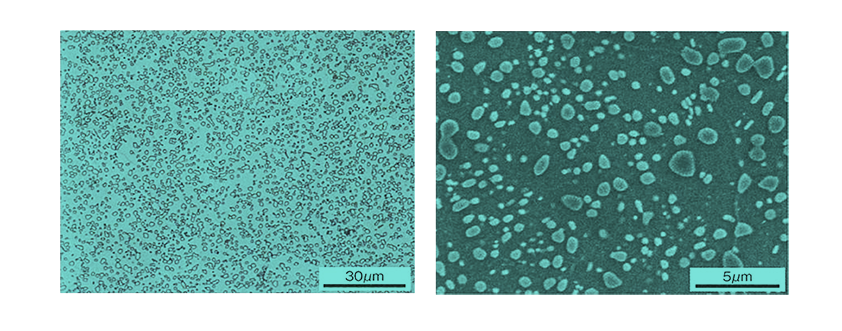

Spheroidizing annealing is performed by various methods, and the most appropriate means is applied depending on the species and prestructural conditions.

Main spheroidizing annealing methods

(A) Prolonged heating method

Long-time heating is performed at a temperature just below the transformation point Ar1.

(B) Repeated heating and cooling method

Heating and cooling are repeated just above the transformation point Ac1 and just below Ar1, followed by slow cooling. The phenomenon is that cementite fragmentation occurs at temperatures above the transformation point Ac1 and spheroidization occurs at temperatures below Ar1.

(C) Isothermal slow cooling method

After heating to 760~780℃, it is cooled to 700~720℃, held at that temperature for several hours, and then slowly cooled to 650℃, followed by air cooling. This method is most commonly used on an industrial scale because it can be applied to various types of ropes and is easily controlled.

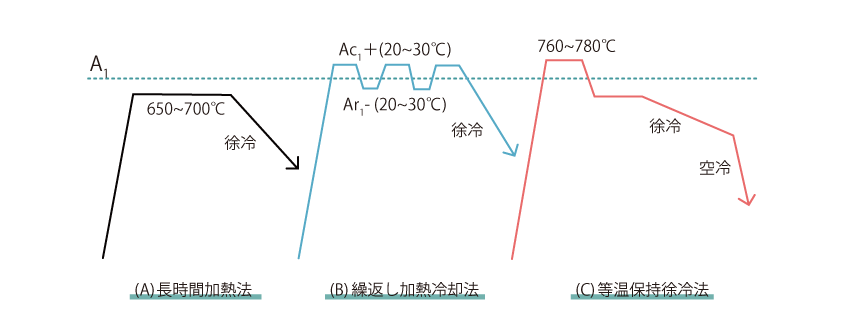

Treated products with good spheronization are sufficiently softened, while those with insufficient spheronization also have a large number of plate-like Fe3C, indicating that they are also insufficiently softened.