Tamayakin’ initiative

Tamayakin’ initiative

HEAT TREATMENT USING ISOTHERMAL TRANSFORMATION (TTT)

Return to list

Return to list

Overview.

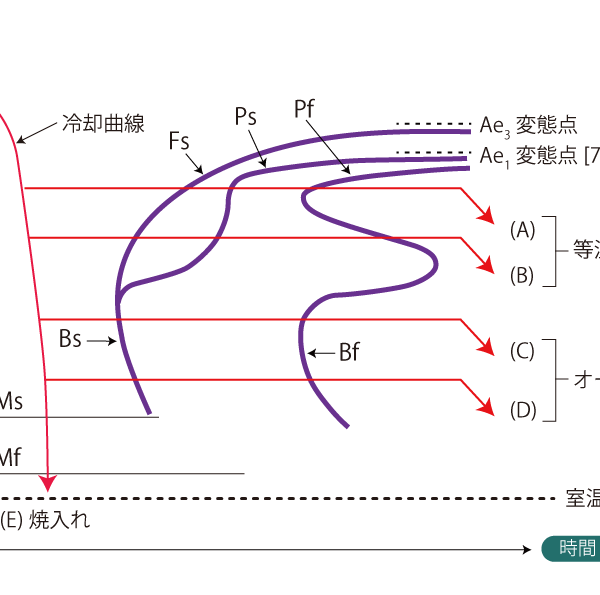

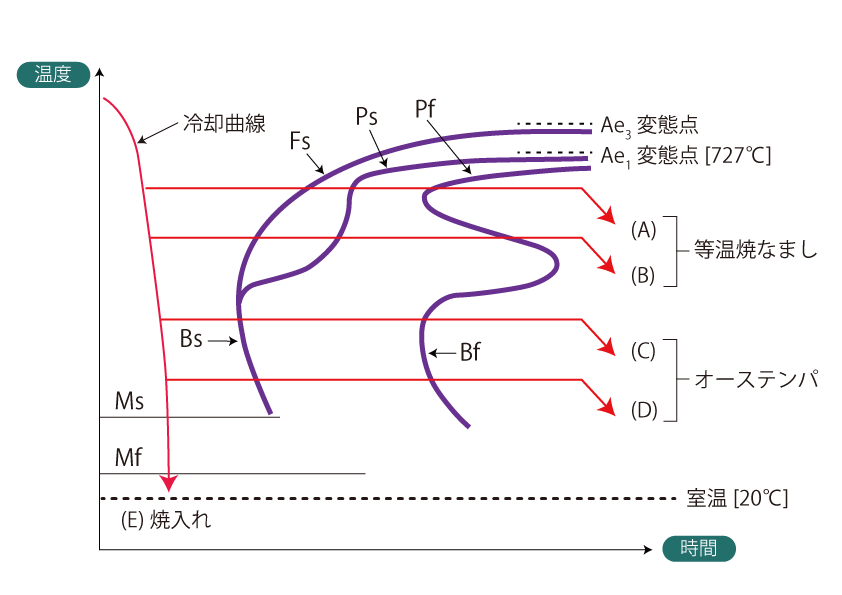

Isothermal heat treatment using isothermal transformation includes isothermal annealing, austempering, and martempering, each with different cooling methods and heat treatment purposes.

01 Isothermal annealing

As shown in (A) and(B) above, this annealing method involves rapid cooling from the austenitizing temperature to near the nose of the TTT curve (550~650°C), followed by isothermal holding until the transformation is complete. Since the processing time is much shorter than that of full annealing, this method is often used for alloy steels for machine structural purposes and high-alloy steels. The resulting metallurgical structure is ferrite + carbides as in complete annealing.

02 austempa

In this process, the austenitizing temperature is the same as the normal quenching temperature, and the specific cooling operations are shown in (C) and(D) in the figure above: the material is quenched in a heat bath maintained at a predetermined temperature above the Ms point, and then pulled up and cooled after the transformation of the supercooled austenite is completed by holding at an isothermal temperature. The resulting microstructure is bainite, also known as bainite quenching is also called bainite quenching.

The temperature of the heat bath ranges from 300~500°C, with most examples around 400°C. The lower the temperature, the higher the hardness. Austempered products are often used as a heat treatment method for springs because they exhibit more tenacious properties than normal quenched and tempered products.

03 Maltempa.

As shown in the figure above, this treatment is performed by quenching in a heat bath maintained at a temperature just above or just below the Ms point from the quenching temperature, holding at isothermal temperature until the surface and center of the treated product reach the same temperature, and then pulling out and air cooling before bainitic transformation takes place. This process gradually progresses the transformation from undercooled austenite to martensite, and the entire treated product is cooled uniformly, reducing quench cracking and quenching deformation.

During the cooling process, the steel must be quenched rapidly up to the isothermal holding temperature to avoid ferrite precipitation and pearlitic transformation, and the applicable steel grades are limited to those with good hardenability. Also known as Marquenching and is also known as staircase quenching or time quenching as cooling operations.

Name and metallographic structure of isothermal heat treatment

| symbol | Name of heat treatment | metallographic structure |

| (A)(B) | isothermal annealing | FERRITE + PERLITE [(B) IS FINER AND HARDER]. |

| (C)(D) | austempa | BAINITE [(C): UPPER BAINITE, (D): LOWER BAINITE]. |

| (E) | General hardening | Martensite [hardest]. |

| (F)(G) | MARTEMPA (MARQUENCHI) |