Tamayakin’ initiative

Tamayakin’ initiative

Tempering (2) - Metallurgical Structure

Return to list

Return to list

Overview.

Tempering is the process of precipitating carbides from the supersaturated solid dissolved carbon by quenching, which changes the fabric from martensite to ferrite.

01 Microstructural changes associated with tempering

Martensite produced by quenching is commonly referred to as hardened martensite.

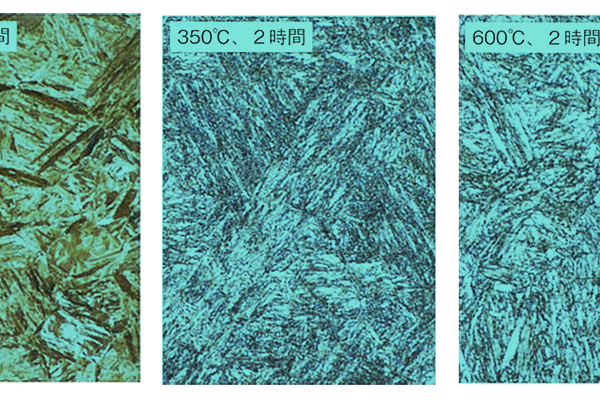

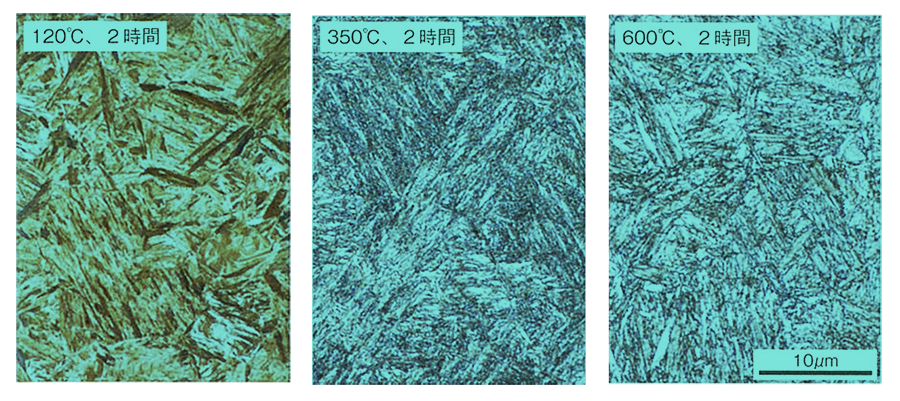

MICROSCOPIC MICROSTRUCTURE OF QUENCHED AND TEMPERED SCM435 (QUENCHED AT 1000°C)

The quenching temperature in the above figure is 1000°C to clarify the metallographic morphology. the microstructure when tempered at 120°C remains in the form of quenched martensite, but as the tempering temperature increases, the fabric changes to ferrite.

02 Carbides precipitated by low temperature tempering

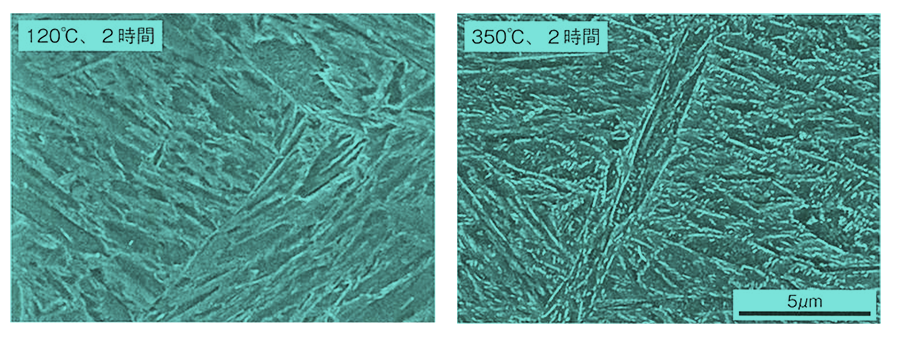

When quenched martensite is heated at 100~200°C, transition carbides ( thermally unstable and change to Fe3C at higher heating temperatures), which are epsilon carbide ( Fe2-2.5C ) precipitates. It is very fine and difficult to observe by ordinary SEM as shown in the figure below.

At 350°C, the precipitation of fine needle-like carbides can be observed. However, tempering at temperatures in the 350°C range will cause embrittlement ( called low-temperature tempering embrittlement), so we recommend avoiding tempering at temperatures in this range.

03 Carbides precipitated by high temperature tempering

High-temperature tempering refers to tempering in the range of 400-650°C and is applied to many grades of steel, including machine structural steel.

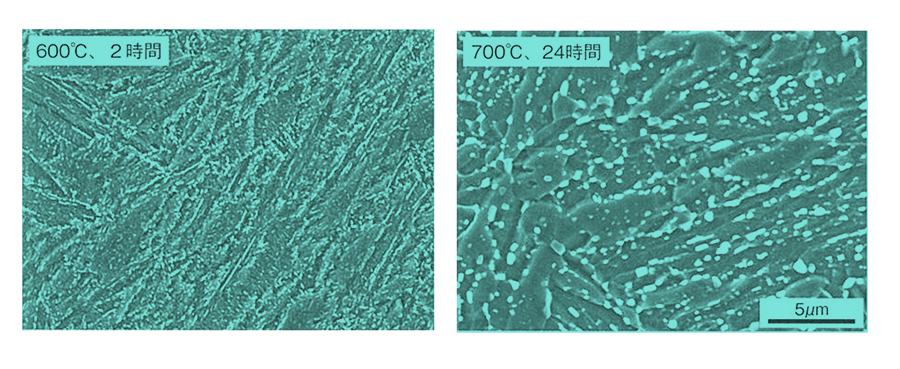

MICROSTRUCTURE OF SCM435 TEMPERED AT HIGH TEMPERATURE (SEM IMAGE)

As an example, the above figure shows the metallographic structure (SEM image) of SCM435 tempered at 600°C for 2 hours and at 700°C for 24 hours. Furthermore, after tempering at 700°C for a long time, it is clear that the carbides precipitated by tempering have a spherical shape.