Tamayakin’ initiative

Tamayakin’ initiative

Carbides in Steel Materials (1) - Types and Roles

Return to list

Return to list

Overview.

The general metallurgical structure of steel materials is composed of iron (Fe)-based fabrics and carbides, with different types of carbides depending on the chemical composition.

01 Types of carbides

Present in steel materials Carbides There are various types of carbides such as M3C type, M23C6 type, M7C3 type, M6C type, M2C type, and MC type, which are determined by the simplified content and the type and content of alloying elements. M for this carbide type is Metal (metal). For example, M in M3C type carbides is mainly Fe, while M6C type carbides require W or Mo in addition to Fe.

| type (e.g. of machine, goods, etc.) | crystal structure | HARDNESS (HV) | Carbides in utility steel | MAIN JIS STEEL GRADES |

| M3C | orthoclinic crystal | 1150~1340 | Fe3C, (Fe,Cr )3C | SK85, S45C, SUP6 |

| M23C6 | face-centered cubic crystal | 1000~1800 | Cr23C6, (Cr,Fe )23C6 | SUS420J2, SUS440A |

| M7C3 | hexagonal crystal | 1800~2800 | Cr7C3, (Cr,Fe )7C3 | SKD11, SKD61, SKD1 |

| M6C | face-centered cubic crystal | 1600~2300 | (Fe,Mo )6C, (Fe,W )6C | SKD4, SKH51, SKH57 |

| M2C | hexagonal crystal | 1800~3000 | Mo2C, W2C | SKH51, SKH57, SKH58 |

| MC | face-centered cubic crystal | 2250~3200 | VC( V4C3 ) | SKH53, SKH54, SKH57 |

02 M3C type carbide

The basic carbides present in steel areM3C type In the case of alloy steels containing small amounts of Cr and Mo, some of the Fe atoms are replaced by these alloying elements.

03 M23C6 and M7C3 type carbides

The M23C6 and M7C3 types are carbides unique to high Cr steels, and are indicated as (Cr,Fe )23C6 and (Cr,Fe )7C3 in practical steels. Even in high Cr steels, the ratio of Cr content to C content determines whether the carbides present are of the M23C6 or M7C3 type.

XRD profiles of carbides extracted from 13Cr steels with different carbon contents

In general, the M7C3 type is coarser than the M23C6 type, but even the M7C3 type is fine for steel grades with low C content.

Metallographic images of M23C6 andM7C3 type carbides

04 M6C, MC and M2C type carbides

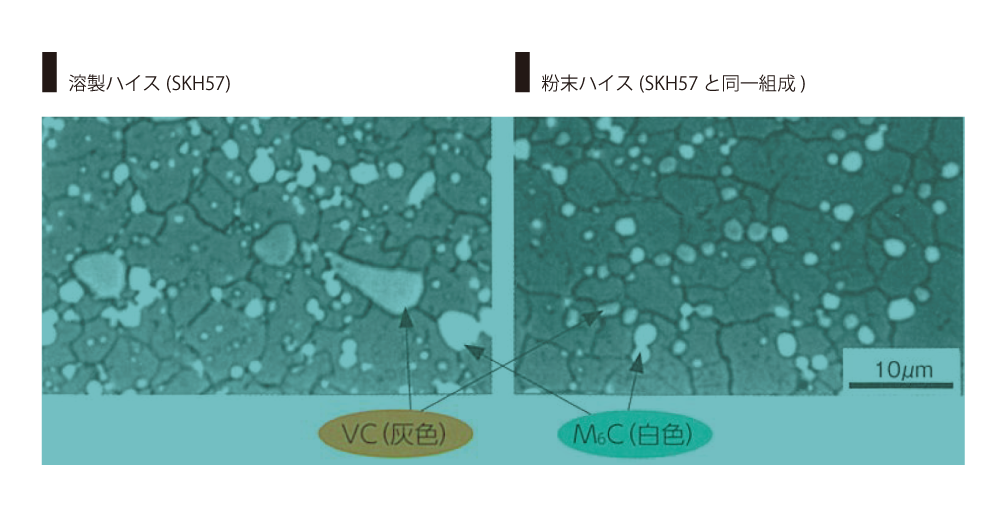

M6C type and MC type are typical carbides of high-speed tool steels, especially VC of MC type is harder than other carbides and contributes greatly to wear resistance. In general, VC is coarse and therefore has a disadvantageous effect on toughness, but in the case of HSS powder, all carbides, not only VC, are fine.

UNSOLVED CARBIDES IN HIGH-SPEED TOOL STEEL (COMPOSITION IMAGE BY SEM)

M2C type is precipitated when high-speed tool steel is tempered at about 550°C in practical steel grades, and contributes to the wear resistance of the product.