Tamayakin’ initiative

Tamayakin’ initiative

Return to list

Return to list

Overview.

There are three main processing methods for steel products. Forming, removal, and addition processing.

01 Type of processing

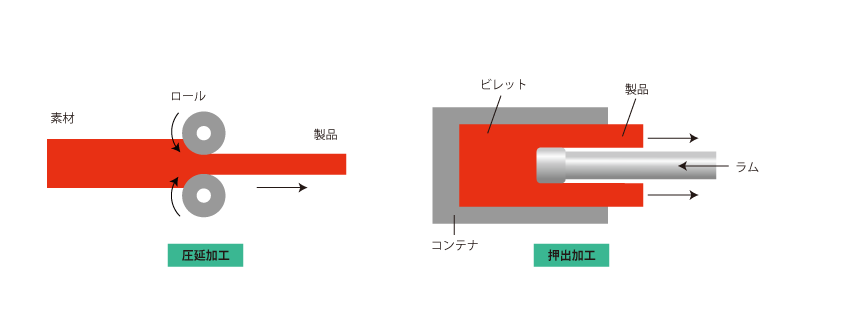

| Plastic forming (rolling, extrusion, cold forging, hot forging, drawing, shearing, bending, rolling) | |

| Molding process | Casting (sand casting, burnout model casting, lost wax, die casting, molten metal forging, thixomolding) |

| POWDER COMPACTION (COMPRESSION MOLDING, SINTERING, POWDER INJECTION MOLDING, MECHANICAL ALLOYING, HOT ISOSTATIC PRESSING (HIP)) |

In the molding process, there is almost no material loss because the shape of the raw material is simply changed.

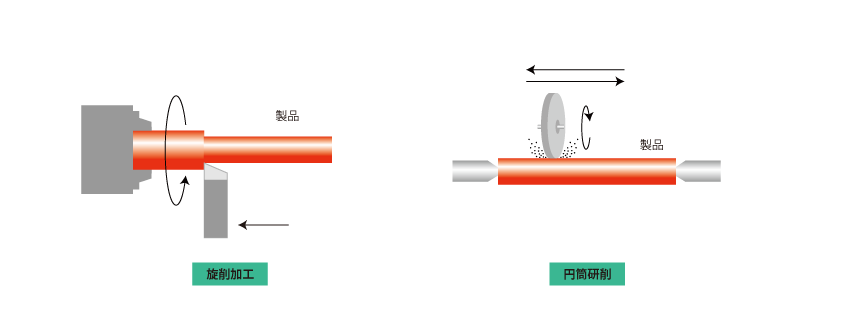

| Cutting (turning, planing, shaping, drilling, reaming, boring, broaching, milling) | |

| removal process | Grinding (surface grinding, cylindrical grinding, internal grinding, centerless grinding, honing, lapping, barrel polishing) |

| Special processing (electrical discharge machining, laser machining, electron beam machining, ultrasonic machining, chemical polishing, electrolytic polishing) |

In removal processing, there is a lot of material loss because unnecessary parts are removed.

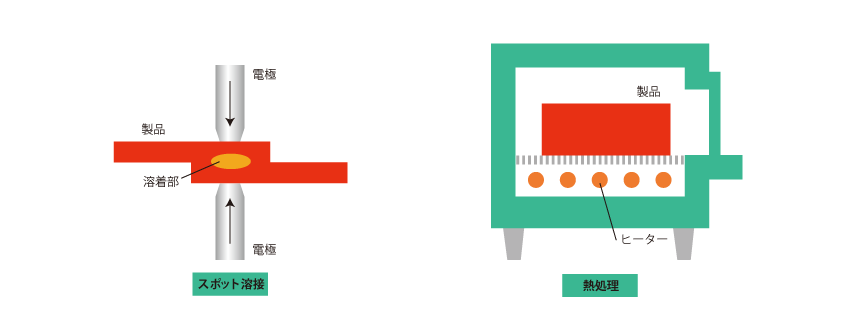

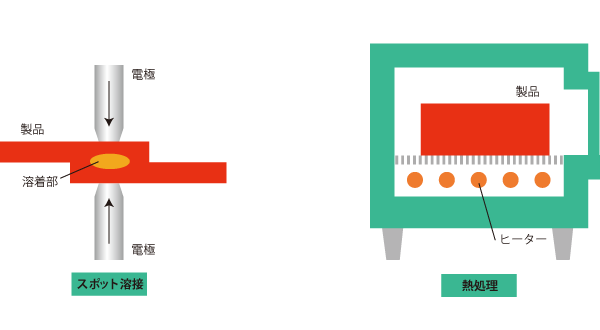

| Joining (gas welding, arc welding, spot welding, diffusion bonding, brazing, bonding, pressure welding, fitting, press fitting) | |

| additive processing | Heat treatment (annealing, tempering, quenching, tempering, austempering, induction hardening, carburizing, and nitriding) |

| SURFACE TREATMENT (ELECTROPLATING, CHEMICAL PLATING, ANODIC OXIDATION, HOT DIP PLATING, PAINTING, CONVERSION COATING, PVD, CVD) |

Additive processing has different effects that can be obtained, such as improved properties and cost reduction, without changing the shape of the product.

02 Molding process

Forming processes include plastic forming, casting, and powder forming. Molding is suitable for high-volume production of the same product because it uses a mold to form the product. However, it is not suitable for high-mix low-volume production because the mold changes as the shape of the product changes. Rolling and extrusion in plastic forming are processing methods with almost no material loss.

03 removal process

Removal processing includes cutting, grinding, and special machining. Removal processing is a processing method with high material loss. Although the material yield is not good, it is a highly versatile process that can be used to process different products by simply changing the machine tools.

04 additive processing

Additive processes include joining such as welding and brazing, heat treatment such as quenching and tempering and carburizing and quenching, and surface treatment such as plating and painting. Joining makes it possible to combine different types of materials. Heat treatment and surface treatment can improve the performance and quality of products.