Tamayakin’ initiative

Tamayakin’ initiative

Return to list

Return to list

Overview.

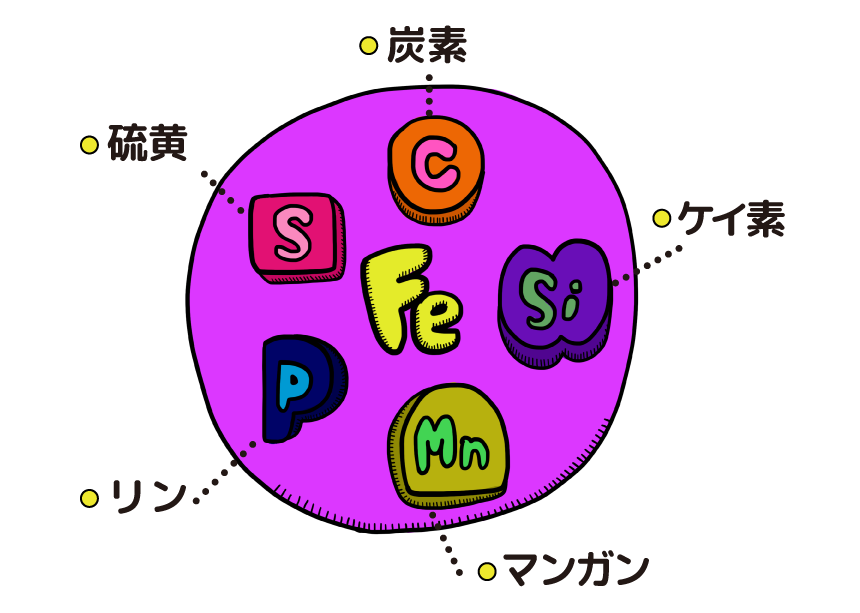

TAMAYAKIN Co. About steel, the material of heat treatment. The main component of steel is iron (Fe), but it also contains carbon among its other components. Steel is classified into pure iron, steel, and cast iron according to the amount of carbon.

01 What is Steel?

The main component of steel is iron (Fe).

Other elements that must be present are carbon (C), silicon (Si), manganese (Mn), phosphorus (P), and sulfur (S).

Carbon is a particularly important element. Steel is classified according to its carbon content.

Steel with less than 0.02% carbon is called pure iron; steel with more than 0.02% carbon is called steel.

Of the five elements in steel, phosphorus (P) can cause delayed fracture and makes the steel brittle when used at low temperatures.

Sulfur (S) also causes brittleness when steel is used at high temperatures.

Both phosphorus (P) and sulfur (S) are toxic to steel.

02 Iron and Steel Crystals

Steel is composed of a set of crystals as shown above.

The boundary surfaces between these crystals are called grain boundary and the boundary surfaces are called grain boundaries.

The boundary surfaces are called crystal grain is called a grain boundary.

The size of these grains is called crystal grain size is called

Overall, fine grain steels have better properties than coarse grain steels.

This is also true for nonferrous metals. If the annealing temperature is too high and the grains become coarse, plastic working may cause cracking even after sufficient softening.

| nature | Fine grain steel is better than coarse grain steel. |

|---|---|

| machinability | Not so good. |

| Room temperature processability | favorable |

| Finished surface | favorable |

| tensile strength | low-born |

| yield point | low-born |

| stretching (e.g. body when waking up) | big |

| aperture (e.g. camera, iris, etc.) | big |

| Impact value | big |

03 Steel Symbols

The name of a steel material represents the symbol of the steel material and its meaning.

For example, the first symbol S is the symbol for S teel (steel).

The symbols that follow represent shape, application, alloying elements, etc. The SPC and SPH P for SPC and SPH is P late (plate) in SPC and SPH, and W is the W ire(line), SUP's U is the U se (use), and P is S p ring(spring) in the SCM. C is the S p ring (spring), and C r(chromium), and M is Cr (chromium) and M o (molybdenum).

| symbol | name | meaning |

|---|---|---|

| SUSPENDED SOLIDS | Rolled steel for general structural purposes | S=Steel S=Structure |

| SPC | cold-rolled steel sheet | P=Plate C=Cold |

| SPH | Hot-rolled mild steel sheet | H=Hot (hot) |

| S-C. | Carbon Steel for Machine Structural Use | C=Carbon |

| SCM | Alloy steel for machine structural purposes (chrome molybdenum steel) | C=Cr (Chromium) M=Mo (Molybdenum) |

| STEAM LOCOMOTIVE | Carbon Tool Steel | K=Kogu(tool) |

| SKH | High-speed tool steel | H=High speed |

| SYMMETRIC DIGITAL SUBSCRIBER LINE | Alloy Tool Steel (Die Steel) | D=Dies |

| SUS | Stainless Steel Rod | U=Use S=Stainless |