Tamayakin’ initiative

Tamayakin’ initiative

accustoming oneself to a certain taste

Return to list

Return to list

Overview.

Since annealed products are slightly harder than fully annealed products, they are sometimes used to improve machinability or as an alternative treatment to quenching.

01 Normalizing method and features

Normalizing is a common heat treatment for mechanical structural ropes. It is an operation in which the material is heated to a temperature higher than its transformation point and then air cooled. The temperature is held at a higher temperature than the transformation point and then cooled by air. Hot forged steel has coarse grains and a non-uniform structure. crystal grains become finer and the structure becomes homogeneous. The annealing process makes the crystal grains finer and the structure more homogeneous.

Fully annealed machine structural steels are too soft to be machined. Therefore, since quenching slightly hardens the steel, it is often applied to improve machinability, and is sometimes used as an alternative treatment to quenching.

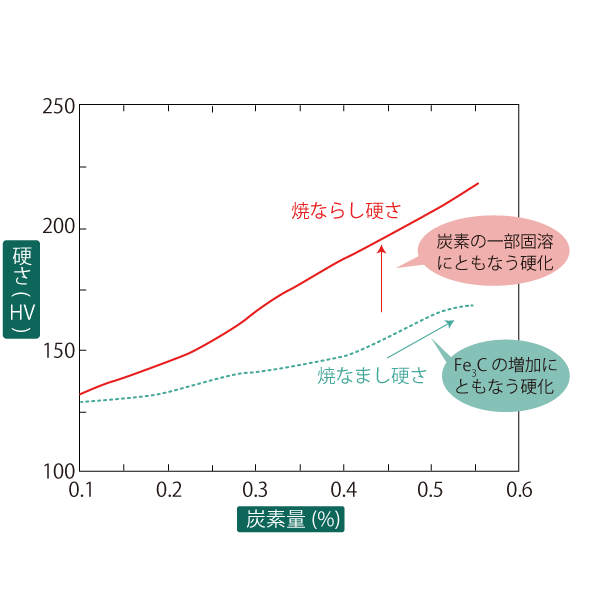

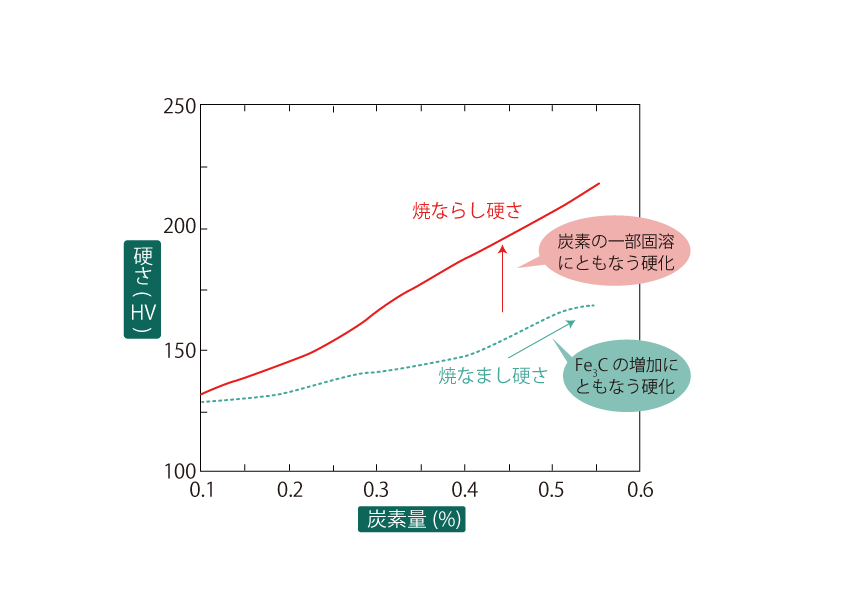

The following chart shows the relationship between average hardness and carbon content for fully annealed and annealed machine structural steel (25 mm diameter specimens). It is clear that the hardness after annealing is higher than that after full annealing, and the higher the carbon content, the higher the hardness.

02 Metallographic structure

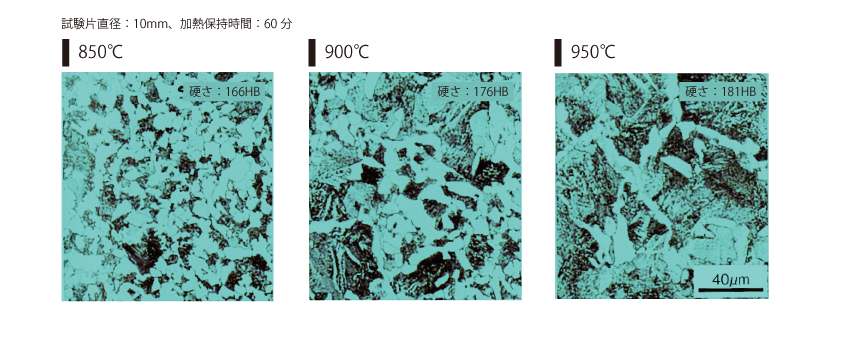

The metallurgical structure obtained by annealing is a mixture of ferrite and pearlite. However, different austenitization temperatures result in different percentages of ferrite and pearlite, even for the same size and grade. The higher the austenitization temperature, the more pearlite is occupied and the higher the hardness.

| class of vertebrates comprising the tetrapods | Temperature (°C) | HARDNESS (HB) |

| S15C | 880~930 | 111~167 |

| S20C | 870~920 | 116~174 |

| S25C | 860~910 | 123~183 |

| S30C | 850~900 | 137~197 |

| S35C | 840~890 | 149~207 |

| S40C | 830~880 | 156~217 |

| S45C | 820~870 | 167~229 |

| S50C | 810~860 | 179~235 |

| S55C | 800~850 | 183~255 |

MICROSTRUCTURE AND HARDNESS OF S35C ANNEALED AT VARIOUS TEMPERATURES

As shown in the figure above. As the austenitization temperature increases, the ferrite content decreases and the pearlite occupancy increases, and at the same time, a coarsening of the crystal grains can be observed. At the same time, the crystal grains become coarser.

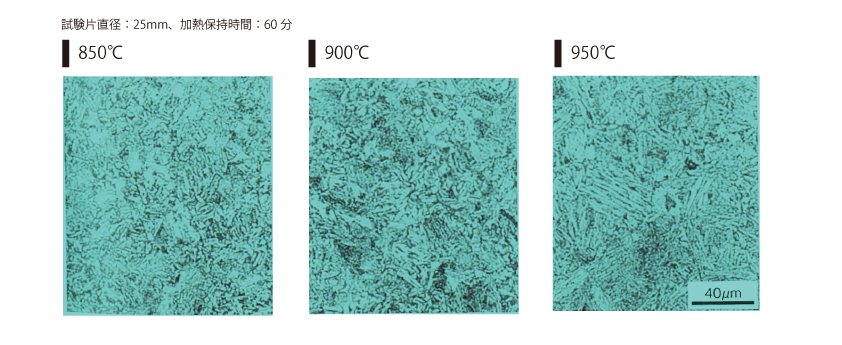

MICROSCOPIC MICROSTRUCTURE OF SCM435 ANNEALED AT VARIOUS TEMPERATURES

IN THE CASE OF ALLOY STEELS FOR MACHINE STRUCTURAL USE, THE CCT CURVE IS ON THE LONG SIDE COMPARED TO THAT OF CARBON STEEL, SO THERE IS NO CLEAR DISTINCTION BETWEEN FERRITE AND PEARLITE AS IN THE CASE OF FULLY ANNEALED STEELS, AS IS CLEAR FROM THE ABOVE FIGURE. THE HARDNESS OF THESE STEELS CAN BE AS HIGH AS 280~285 HB, WHICH IS CONSIDERABLY HIGHER THAN THAT OF CARBON STEEL.