Tamayakin’ initiative

Tamayakin’ initiative

Types and Classification of Heat Treatment

Return to list

Return to list

Overview.

Heat treatment includes heat treatment in which the entire treated material is heated and cooled to impart predetermined properties, and surface heat treatment in which only the surface is treated to impart predetermined properties.

01 Overall heat treatment

| name | Main applicable steel grades | Main processing purpose | |

| annealing | perfect annealing | Steel for machine structural use in general | Tissue conditioning and softening |

| spheroidization annealing | Steel for machine structural use in general | Improvement of plastic formability, imparting toughness | |

| Carbon tool steel, low alloy tool steel, bearing steel | Provides toughness, improves machinability | ||

| low-temperature annealing | Steel materials in general | Removal of stress (machining, welding, casting), softening | |

| accustoming oneself to a certain taste | Steel for machine structural use in general | Tissue refinement, tissue homogenization, hardening | |

| hardening | Steel for machine structural use in general, spring steel, bearing steel | Hardening, improved mechanical strength | |

| Tool steels in general, martensitic stainless steels | Hardening, improved wear resistance | ||

| annealing | 100~200°C | Carbon tool steel, low alloy tool steel, die steel | Adding Toughness |

| 400~450°C | Spring ropes, carbon tool steel | Assignment of spring characteristics | |

| 450~650°C | All steels for machine structural use, martensitic stainless steels | Adjustment of mechanical properties | |

| 500~600°C | High-speed tool steel, die steel | Improvement of abrasion resistance, imparting toughness | |

| sub zero processing | Tool steel for cold forming, martensitic stainless steel | Improved abrasion resistance, prevention of aging | |

| Solution treatment |

Austenitic stainless steel | Prevention of intergranular corrosion, softening | |

| Precipitation hardening stainless steel, maraging steel | Solid solution of alloy components | ||

| Precipitation hardening treatment | Precipitation hardening stainless steel, maraging steel | Improved mechanical strength, imparting spring characteristics | |

| isothermal treatment |

austempa | Alloy steel for machine structural purposes, spring steel | Providing toughness and spring properties |

| Maltempa | Alloy Tool Steel, Alloy Steel for Machine Structural Use | Quench hardening with reduced quench distortion | |

There are various heat treatments for steel materials, with different grades applied and treatment purposes. For example, in the case of machine structural steel and tool steel, annealing is used to soften, quenching to harden, and tempering to give toughness. However, even if the heating and cooling operations are exactly the same, the names of the heat treatments change when the target steel grade is different or the purpose of the treatment is different. For example, quenching and solution treatment are both operations that involve rapid cooling from a high temperature, but quenching is for hardening, while solution treatment is for softening, as in the case of austenitic stainless steel.

Annealing and quenching are referred to as ordinary heat treatments, while austempering and martempering, which involve special cooling operations, are often classified as special heat treatments. Austempering is a process to obtain a bainite structure by cooling rapidly in a heat bath at a controlled temperature of about 400°C and holding at that temperature for a specified time, and is often used as a heat treatment method for springs. It is also used as a heat treatment method for springs. Martempering is used as a quenching method to minimize deformation.

02 Names of cooling operations and heat treatments

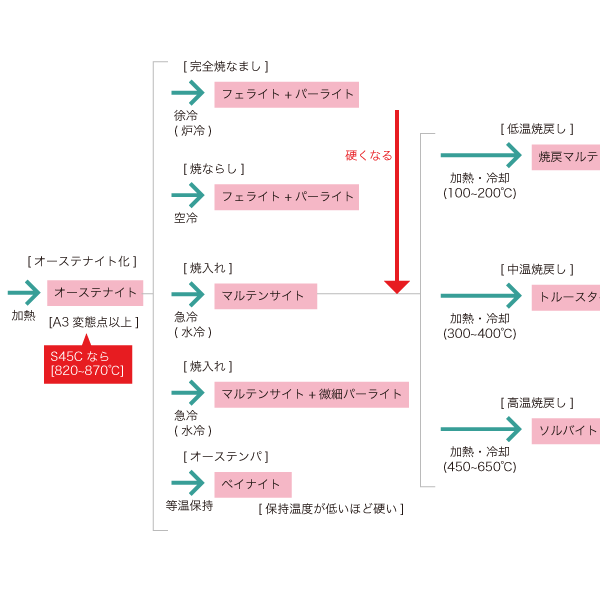

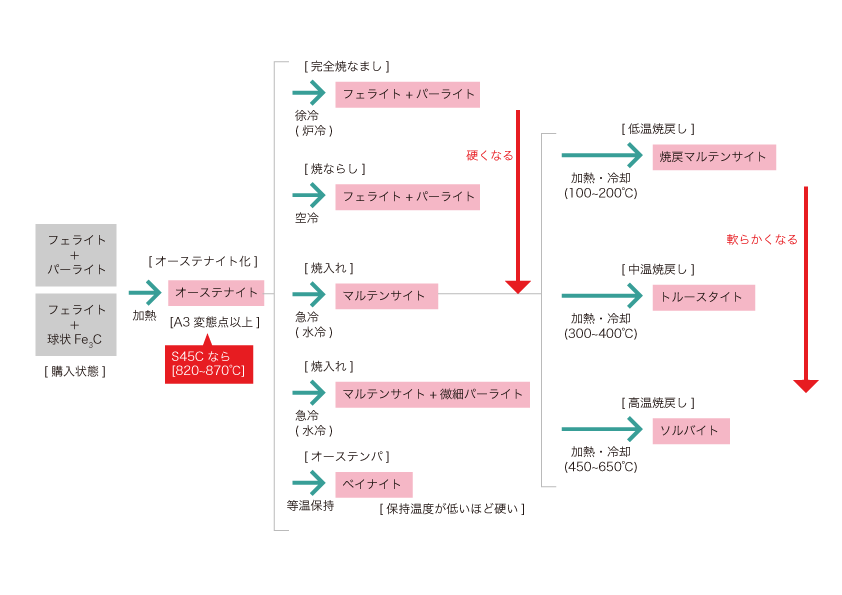

Using machine structural steel, the basis of heat treatment, as an example, the relationship between heating and cooling operations, microstructural changes, and the name of the heat treatment is shown. Note that the heating temperature is above the A3 transformation point to achieve a complete austenitic structure, and the subsequent cooling or heating operations ant harm are described. For example, for S45C or SCM440, the standard austenitizing temperature for quenching them is 820~870℃.

From this figure, it can be seen that although the heating temperature is the same, the metallurgical structure and the name of the heat treatment change only when the cooling operation is different. The slow cooling operation is called complete annealing, while the air cooling operation is called annealing, both of which have a mixed structure of ferrite and pearlite. Quenching, in which the metallurgy is martensite and the highest hardness is obtained, is performed by quenching with water or oil to accelerate cooling.