Tamayakin’ initiative

Tamayakin’ initiative

low-temperature annealing

Return to list

Return to list

Overview.

Low temperature annealing is performed to remove residual stresses caused by welding, casting, cold working, etc., and to reduce softening and quenching deformation.

01 Microstructural changes associated with recrystallization

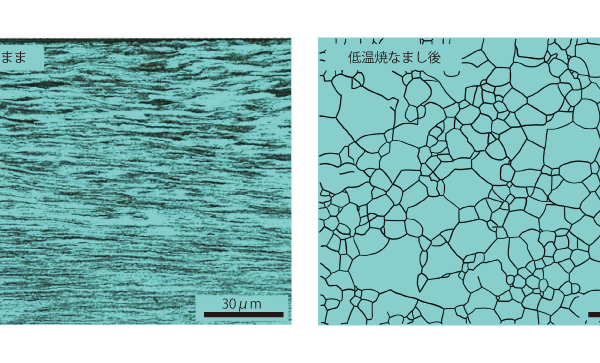

Crystals in cold-worked materials are distorted, elongated, and irregularly arranged. These are Low-temperature annealing the crystals are rearranged as shown in the figure below.

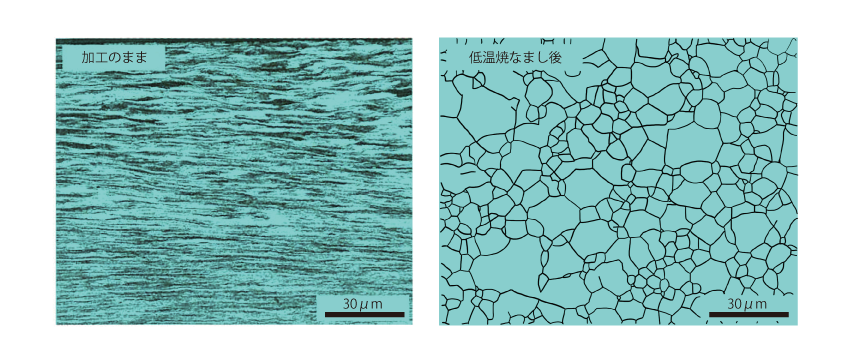

As shown in the figure above, hot-rolled steel sheet (SPHC) is also stretched by cold bending, and many slip lines are generated in the crystal grains. By annealing at low temperature, the crystal grains are rearranged and become more uniform and finer than in the purchased state. Recrystallization temperature The temperature at which this rearrangement occurs is called the recrystallization temperature, which is about 550°C for carbon steel and low-alloy steel.

02 Heating temperature

Residual stresses in steel caused by welding or casting usually disappear and soften when heated to about 550~600℃. The cold annealing temperature of high-alloy ropes is higher than that of carbon ropes and low-alloy steels. The annealing temperature of high alloy ropes is higher than that of carbon ropes and low alloy steels. For example, ferritic stainless steel ropes are 700~900℃ and martensitic stainless steel ropes are 650~750℃. In the case of cold-formed SUS304 springs, low-temperature annealing at about 400°C improves the spring properties and significantly extends the fatigue life of the spring.

03 Low-temperature annealing of piano wire

In the case of piano wire, piano wire rods (high-carbon ropes) are made stronger by cold drawing after pattening, so hardness and microstructural changes are different from those of ordinary cold-worked products.

As shown in the above figure The above figure shows that the material softens when heated above 400°C, and that the hardness gradually decreases in proportion to the increase in heating temperature. The figure shows that the hardness gradually decreases in proportion to the increase in the heating temperature.

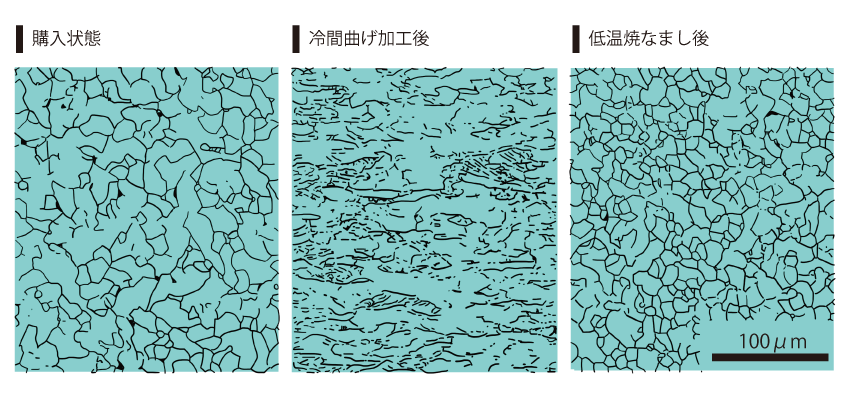

The following figure shows the changes in the microscopic tissue at this time.

The metallurgy before heating appears to be fine pearlite, but it is difficult to determine the crystal grains and metallurgy because it appears to have been stretched long in the working direction due to cold working. This condition remains almost unchanged until the heating temperature reaches about 550°C. When annealed at 700°C, the metallurgical structure is ferrite + spheroidal carbides, and the structure has changed to a spheroidal annealed state.