/

/

| Tamayakin Co., Ltd. "Serving Japan's Heat Treatment Industry Since 1951" |

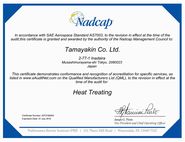

From general mechanical and electrical parts to aerospace and defense components, we have a system in place to meet the various demands of our clients. When catering to the demands of each individual, we adhere to specifications as provided in AMS2750 Pyrometry and our processes are implemented in compliance with heat treatment industry standards such as the required AMS and MIL, while testing is implemented in compliance with ASTM. And we are accredeted by Nadcap for a wide range of heat treating processes. |

|

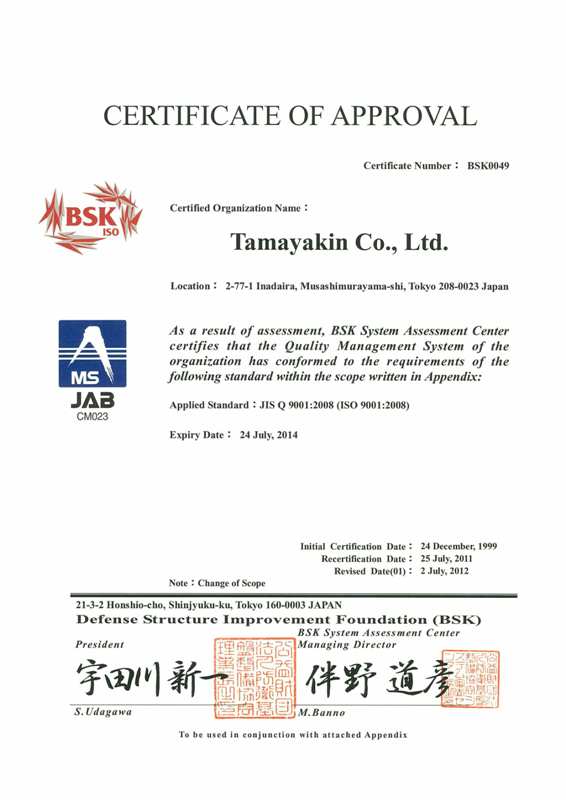

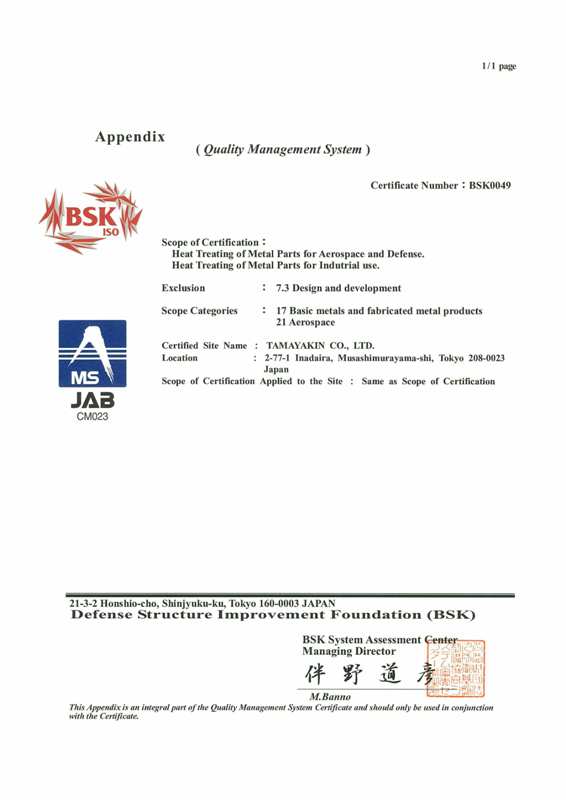

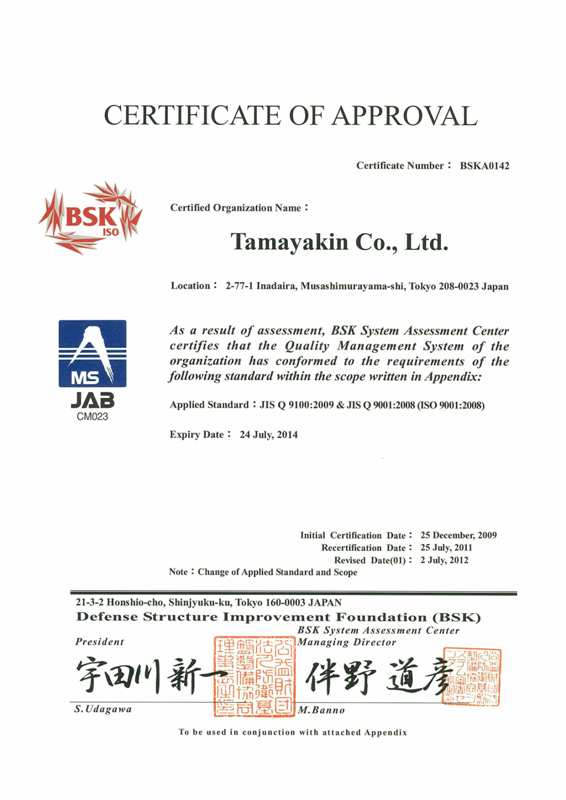

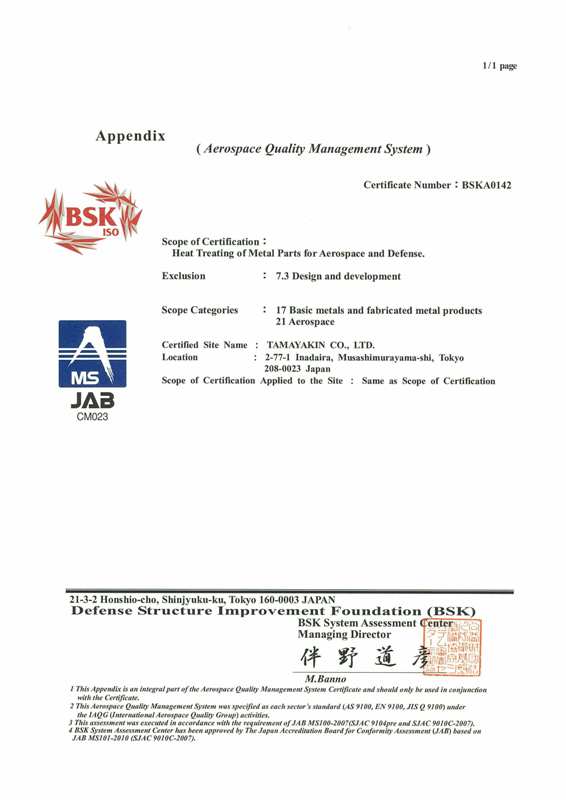

◆ JIS Q 9100 accreditation:

|

|

|

|

◆ Nadcap accreditation:

|

scope page1 |

scope page2 |

And we also can provide carburizing process per AMS spec.